4 Steps on The Way to Supply Chain Leadership

Keith LaBotz - April 27, 2023

Supply chain leadership requires doing things differently, and a company’s digitalization strategy plays a key role.

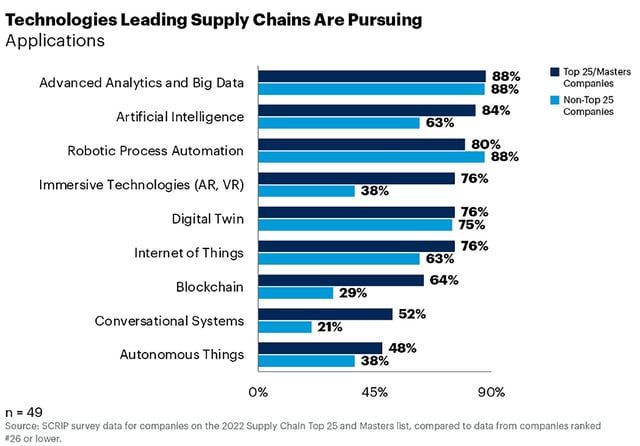

Gartner’s 2022 Supply Chain Top 25 may interest your company; it identifies top-ranked companies for “sustained supply chain excellence” and highlights the practices and strategies that differentiate them. It reveals which innovations the most advanced supply chains are pioneering, and that’s valuable, but not for the reasons you might expect.

The most important insight is not the different technology choices a couple of dozen supply chain leaders make but the need for everyone else to differentiate digitally. The path to supply chain leadership does not “follow the leader” on digital solutions; companies on the right track are more likely to interpret Gartner’s report differently.

Supply chain differentiation results from connecting fundamental customer requirements with supply chain decision-making, and digitalization is a powerful enabler. Every organization represents a distinct combination of circumstances, objectives, people, processes, and strengths. An organization’s supply chain process will reflect these distinctions when technology is appropriately selected and implemented - differentiating itself as unique.

Supply chains don’t need to follow the technology choices of industry leaders - they need to follow a method for selecting and implementing technologies that will best meet their unique requirements. That’s how a supply chain successfully differentiates, and there are four steps your company can act on to make it happen.

1. Establish a Digital Framework: Optimize Planning

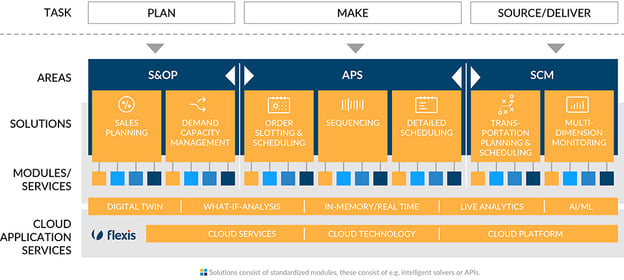

Effective supply chain management is ultimately a function of an organization's proficiency in achieving optimal outcomes, and the right supply chain planning solution will facilitate it. Optimization organizes enterprise apps and functions around a data model, creating a framework for cross-functional decision-making that can guide process improvements.

The immediate cost savings, risk reduction, and sustainability gains are reason enough to take this step, and the framework makes it easier to identify the most effective digital solutions.

For example, the flexis cloud integrates transportation, S&OP, APS, and SCM (logistics) planning around a standard data model. This solution is introduced into existing enterprises and continuously adjusts planning across supply chain processes. The process highlights potential improvements by revealing constraints, vulnerabilities, and opportunities:

- The effects of changing demand, schedules, capacity, and disruptions on supply chain activities, plans, and financials.

- “What-if” scenario planning identifies patterns and structural changes that lead to optimization.

This solution extends visibility beyond daily operations management into long-range forecasting (6 + months) and mid-range tactical planning (3-6 months).

2. Clearly Define Your Company’s Requirements

The goal of digitalization is supply chain optimization, which implies fully automated, intelligent planning and execution. With a framework for optimizing supply chain decisions already in place, identifying and prioritizing process improvements becomes easier.

- Detailed business requirements also become more visible when exploring the role of each function and app in the supply chain process.

- Expected outcomes for the business are easier to identify.

- It enforces a cross-functional analysis, ensuring new solutions align around common objectives.

3. Identify Solutions for Companies with Similar Requirements

Once requirements are known, the search for potential solutions can begin. The quickest way to narrow the list is often learning which solutions are most effective for companies with similar requirements. Your company will likely find the best fit by looking in the same industry and similar size, culture, and capabilities.

While the chosen solution must support your company’s unique needs, similar companies share many of the same workflow and general business practices requirements. What differentiates companies are requirements related to stakeholder expectations and vendors, suppliers, and strategy.

4. Filter Solutions for Companies with Dissimilar Requirements

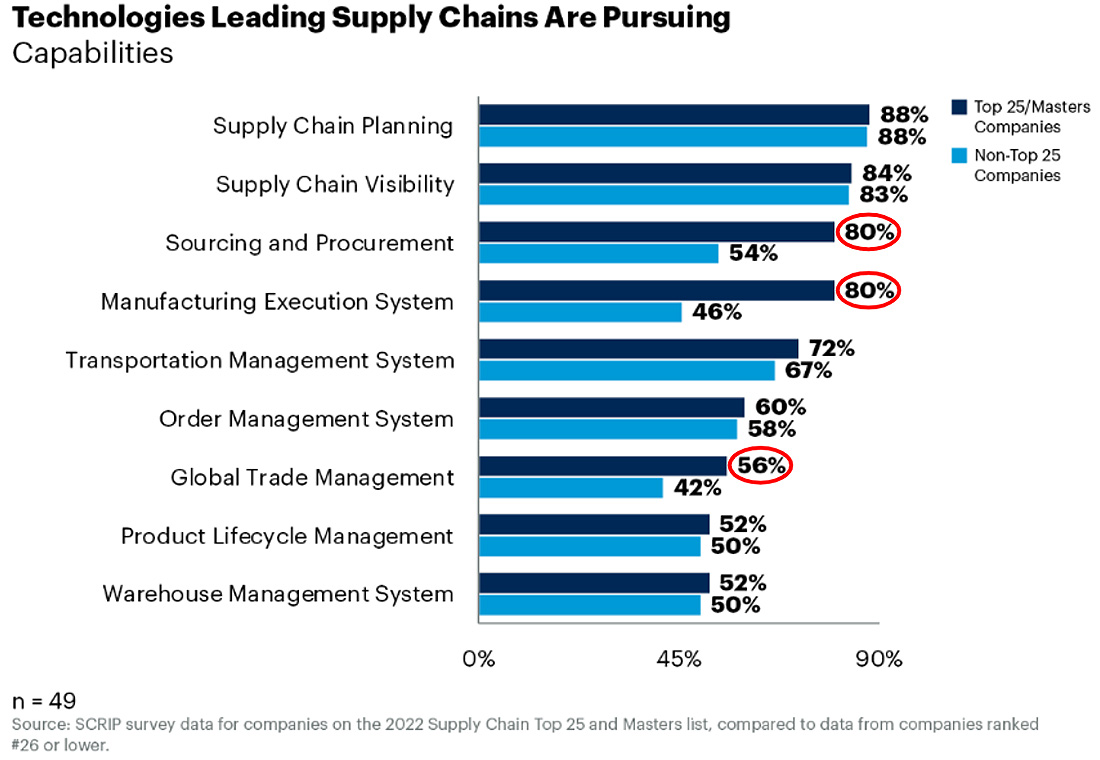

Staying focused on viable candidates requires filtering out the inappropriate ones, and the easiest way to identify them is to identify vendors catering to companies with different requirements. Let’s go back to Gartner’s Top 25 to see how this works.

The name-brand multinationals in the Top 25 may face the same supply chain challenges as every other company, but their requirements differ from most.

- These companies have extensive supply chains of significant depth, which favors a greater capacity and tolerance for risk.

- The scale of their operations means a successful pilot can be deployed in global operations to produce substantial gains, offsetting multiple failed projects. This strategy is out of reach for the majority of companies.

How does that play out in practical terms? The Top 25 differentiated themselves by investing more in sourcing, manufacturing execution, and global trade management solutions. These three areas demand far more collaboration with external partners, presenting significant obstacles.

The focus and the novel solutions of these companies differentiate them in a big way, which is what Gartner lauds in the Top 25. Comparing your company’s requirements to the Top 25 will likely lead your company in a different direction.

Conclusion

Successfully meeting a company’s unique requirements by implementing the most effective digital solutions differentiates supply chain leaders from the rest. Following the four steps in this article will help achieve that, and flexis AG offers the software and services needed to make it happen.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

Or do you want to learn more about the Gartner Top Trends in Strategic Supply Chain Technology 2023?

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers