Two Steps For A Better Digital Strategy

Keith LaBotz - July 20, 2023

The 34th annual State of Logistics Report presents potentially good or bad news for businesses, and it all hinges on their digital strategies. The silver lining? Any company can ensure its digital strategy is on the right track; now is the ideal time.

The report by Kearney reveals U.S. business logistics costs soared to $2.3 trillion, a record-breaking 9.1% of the national Gross Domestic Product. With the recession currently easing transportation prices and volatility, the report’s author encourages organizations to use this lull “to get clear about what is working now and what is needed to ensure resilience for an uncertain future.”

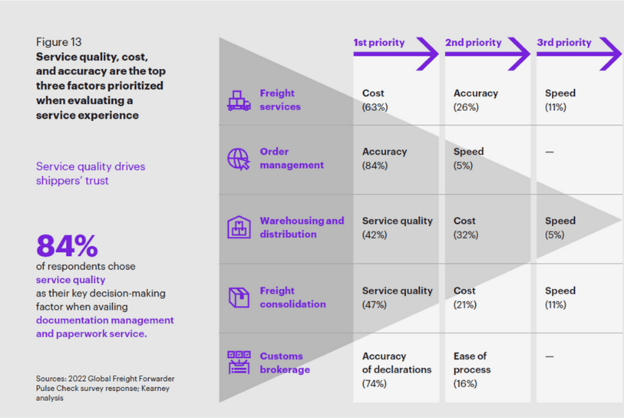

A digital strategy must tackle current and future priorities, and according to Kearney, the top three priorities for transportation carriers and shippers are: improving cost, accuracy, and service quality.

While we can't predict the future with certainty, long-term trends provide some guidance. Previous posts on this blog have emphasized the inevitable progression toward supply chain optimization and the centrality of transportation to this goal. Interestingly, the report underscores a shift in perspective among logistics executives that aligns with this view.

A newfound emphasis among logistics professionals is emerging – changing from purely transactional to a more strategic and holistic view. Likely prompted by the port crisis and from the process of connecting the supply chain dots during digitalization, logistics stands out as the connecting point.

The picture emerging is a more collaborative supply chain; what is becoming clear about the future is that collaboration depends on reliable logistics. An effective digital strategy must prioritize logistics optimization along with addressing the immediate issues previously mentioned.

So, how can your company implement this digital strategy? This article outlines two steps your company can take to make this happen.

1. Emphasize Cost Optimization

Cost optimization takes a holistic view of supply chain costs and relies on what-if analysis to find the optimal balance between outcome and cost. Costs are managed dynamically by improving the utilization of resources instead of downsizing capacity.

This approach to managing costs is crucial during economic uncertainty as it helps protect the strategic role of logistics. Transportation is the core of a supply chain; every business process ultimately impacts shipping and vice-versa. The problem with traditional cost-cutting is that it typically happens within a functional silo, reducing expenses without considering the downstream impact on logistics.

A digital strategy driven by cost optimization will guide planning around efficient logistics, and this approach works equally well in economic booms and busts.

2. Adopt End to End Supply Chain Planning in the Cloud

Cloud solutions offer APIs facilitating seamless integration between enterprise systems and external supply chain partners, enabling real-time visibility, data analytics, and decision-making tools.

Cloud platforms provide a secure way to connect with other software applications and supply chain partners. Operating in the cloud makes achieving economies of scale easier: a solution can rapidly deploy to many sites after a successful pilot.

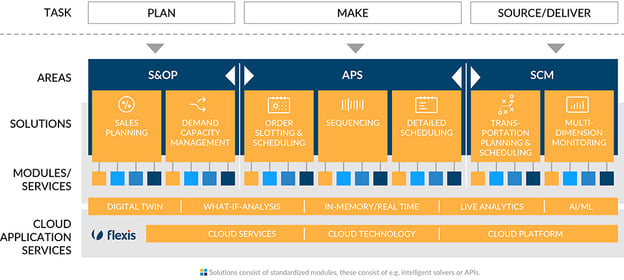

The flexis cloud exemplifies an integrated solution for optimizing logistics cost and performance by fine-tuning demand planning, production, and transportation. A digital twin supporting the functions shown above in multiple sites provides an enterprise with end-to-end visibility.

The flexis cloud exemplifies an integrated solution for optimizing logistics cost and performance by fine-tuning demand planning, production, and transportation. A digital twin supporting the functions shown above in multiple sites provides an enterprise with end-to-end visibility.

The solution incorporates specific transportation functions with continuous planning to optimize all levels of transportation logistics:

- Continuous Planning: Long-range forecasting (6 + months), mid-range tactical planning (3-6 months), and daily operational plans (minutes to 12 weeks of execution) integrated into a single, cohesive view.

- Transportation Planning and Scheduling: Optimizes shipping plans across the logistics network with changing demand, disruptions, and constraints.

- Order Slotting and Demand Capacity Management: Alters production and transportation schedules as demand, transportation, and production constraints change.

- Inbound Freight Optimization: Adjusts supplier shipping and factory production with changes in demand and delivery schedules.

- Consolidation Combines orders into single shipments and multiple shipments into multi-stop truckloads in coordination with production and distribution commitments.

- Loading Optimization: Fully utilizes cargo space and loads for the most efficient unloading sequence of multi-modal containers and trailers.

- Vehicle Routing and Scheduling (VRS): Optimizes delivery routes, multi-stop trips, and transfers for fleet operations.

- Multimodal Optimization: Expands transportation capacity and minimizes costs by combining transport modes like truck, rail, ocean, barges, and air freight.

Conclusion

An uncertain economic climate underscores the need to shore up digital strategies. The strategy must incorporate a holistic approach to optimizing logistics to build a bridge connecting current challenges with future opportunities. The most effective solution for most companies is adopting a cloud solution with end-to-end optimization.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach