Supply Chain Optimization: The Key to A Better Digital Strategy

Keith LaBotz - May 11, 2023

Data and analytics (D & A) are increasingly vital for supply chain success, and a solid digital strategy is the most potent competitive advantage in a digital supply chain.

According to Gartner, organizations must provide high-quality data to enable decision-making from the boardroom to operations. D&A is a crucial enabler for addressing business challenges and opportunities, and an effective digital strategy can ensure these results.

As digitalization increases, decision-making will become faster, and operating without a robust digital strategy will become more challenging. Crafting a practical plan for digital initiatives can be complex, but there is an approach to implementing digital solutions that can catalyze an effective digital strategy.

A digital strategy ultimately leads to supply chain optimization, but can supply chain optimization lead to a digital strategy? Yes, it can if it’s approached correctly and the right technology is used. Here’s how it works.

All digital automation requires translating business rules into decision parameters, and it involves a comprehensive understanding of the following:

- Stakeholder expectations related to supply chain functions, including company goals and objectives.

- Business risks associated with particular operational scenarios and trends.

- The impact of decisions on the organization in response to events, considering cross-functional effects across sourcing, production, and distribution.

- Possible responses considering objectives, constraints, risks, contingencies, and requirements for specific scenarios.

If done correctly, this analysis results in greater clarity and well-defined data parameters for enabling data-driven decisions in supply chain software applications. Implementing this newfound understanding and data in a supply chain optimization solution can lead to an effective digital strategy.

This article will examine how flexis optimization technology can produce an effective digital strategy while significantly improving supply chain performance.

How flexis Technology Produces a Digital Strategy

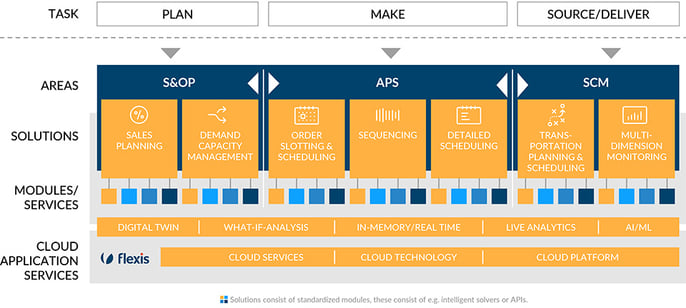

flexis AG provides a suite of solutions for optimizing S&OP, APS, and SCM planning and establishes a supply chain optimization framework. Live Analytics is a flexis technology that detects trends and patterns, calculates probabilities, and discovers hidden relationships between supply chain variables. Supply chain planning is optimized by combining these insights, digitized business rules, and the latest operational data in what-if simulations.

As a cloud solution, flexis solutions employ a digital twin of a company’s supply chain, making integration with enterprise systems, AI analytics, and process improvements straightforward. Accurate forecasts and statistics are valuable inputs for strategic, tactical, and operational decisions.

flexis technology is also helpful for supply chain network modeling, decision modeling, risk analysis, and testing proposed process improvements. Here are a few of the things it can do:

- Determine the optimal response to unexpected changes and their effects across the enterprise.

- Explore the impact of potential process improvements on costs, carbon emissions, and supply chain performance.

- Test the integrity of a decision model before deploying it into the production environment.

Optimizing supply chain planning maximizes profitability and sustainability. It also reveals which process improvements are most valuable and least risky, establishing a priority and path forward for digital solutions. In other words, a digital strategy.

Let’s examine how six process improvements supported by the flexis solution facilitate a digital strategy.

1. Improving Forecast Accuracy and Demand Planning

flexis provides robust end-to-end supply chain planning, automatically predicting changes in demand and capacity and adjusting schedules and plans across enterprise functions in response. Live Analytics enables much of this optimization, so companies can identify trends and patterns usually overlooked.

2. Enhancing Supplier Management

Analyzing data from supplier interactions reveals opportunities for improved collaboration and communication. Monitoring supplier fulfillment can reveal opportunities to minimize freight costs and lead times and reduce their carbon footprint.

3. Optimizing Warehouse Operations

Live Analytics identifies warehouse inefficiencies leading to excessive time, labor, materials, and carbon emissions. Tracking the movement of goods can reveal optimal inventory levels, streamline material handling, and optimize warehouse layouts, lowering energy usage, carbon emissions, and operating costs.

4. Increasing Transportation Efficiency

Analyzing transportation data can reveal opportunities for minimizing freight costs and fuel consumption and increasing sustainability.

- Transportation fleets can determine the optimal EV ratio to gas and diesel-powered tractors.

- flexis solutions for optimizing vehicle routing and scheduling, load planning, and identifying opportunities for multimodal shipping.

5. Reducing Waste

Detecting inefficient utilization of resources in supply chain activities results in reducing waste. Live Analytics can also track the lifecycle of products and materials, identifying opportunities for reuse, recycling, or upcycling.

6. Increasing Supply Chain Resilience

Actual and potential vulnerabilities are detected, allowing timely responses and strategies that mitigate risks. Anticipating disruptions and rapid decisions that can adapt operations is crucial for navigating current challenges and the future's more volatile digital supply chain.

Conclusion

flexis technology unlocks the full potential of a digital supply chain strategy, facilitating initial modeling, supply chain optimization, and process improvements. The capabilities discussed significantly increase supply chain resilience and profitability. They also reveal the risks and benefits of potential digital solutions - a de facto digital strategy based on live data.

If you want to learn more get your Supply Chain Manager’s Guide to AI

In this Guide you will learn:

-

Why AI will define the future of the global supply chain

-

Application of AI for manufacturers

-

Integration AI with S&OP

- Keys to successful implementation

Or do you want to learn more about the Gartner Top Trends in Strategic Supply Chain Technology 2023?

Get your download here:

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach