Understand Circular Economy in The Manufacturing Industry

Ute Strohmaier - February 27, 2024

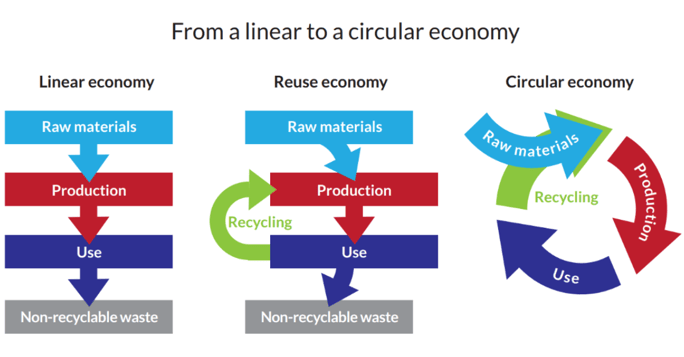

What is circular economy?

A circular economy is an economic system that aims to minimize waste and make optimal use of resources. In a classic economic cycle, goods are produced, used and then disposed of as waste. In contrast, a circular economy aims to avoid waste and use products, materials and resources for as long as possible through recycling, refurbishment and reuse.

What are the drivers?

The drivers for a circular economy are complex and include a combination of economic, environmental and regulatory factors.

1. Regulations in the EU and Germany:

Policy frameworks: the European Union, including Germany, has been at the forefront of promoting circular economy principles through comprehensive regulatory frameworks. Policies such as the EU Circular Economy Action Plan and the German Circular Economy Program outline specific measures to improve resource efficiency, waste management and recycling.

Extended Producer Responsibility (EPR): EU and German regulations often emphasize the principle of extended producer responsibility and require manufacturers to take responsibility for the entire life cycle of their products. This includes recycling-friendly design, waste collection and recycling infrastructure.

Waste management targets: Strict waste management targets set by the EU and Germany promote the need for circular processes. These targets incentivize companies to implement circular strategies to achieve recycling and recovery targets and reduce the environmental impact of waste.

2. The finite nature of resources:

Resource scarcity: the realization that many natural resources are finite and running out is a fundamental driver for a circular economy. As traditional linear models deplete resources, a new approach becomes essential to maximize the use of existing materials through recycling, remanufacturing and reprocessing.

Risk mitigation: Understanding the limits of available resources mitigates the risks associated with resource scarcity. Circular economy practices, such as the reuse of materials and products, help to secure and diversify resource supply chains and reduce dependence on scarce resources.

Economic opportunities: Companies that are aware of the finite nature of resources see economic opportunities in the introduction of circular economy practices. By developing products that are durable, recyclable and reusable, companies can gain a competitive advantage, reduce costs and tap into new markets and target groups that prefer sustainable products.

What are the problems and obstacles:

-

Remanufactured parts must be covered by a warranty equivalent to that of new parts.

-

The availability of a sufficient quantity of high quality used parts for effective remanufacturing poses difficulties in accurate forecasting.

-

Determining the condition and price of old parts, such as a car clutch, requires efficient processes that may include inspections with AI recognition for optimal detection.

-

In the future, specialists will presumably offer themselves as service providers for manufacturers for this task.

-

The initiation and execution of the logistics process for remanufacturing must be both fast and efficient.

-

When remanufacturing a vehicle, managing the remanufacturing of different supplier parts by an original equipment manufacturer (OEM) requires the development of new processes and capabilities. This means that in the future, integrated supply chains for spare parts will need to be orchestrated.

The current industrial landscape: shifting to sustainable design

In today's manufacturing landscape, products have historically been designed without resource constraints in mind. Suppliers have traditionally acted as buyers rather than designers. However, a significant shift is underway as the industry is now adopting modular designs for new products that reflect a heightened awareness of limited resources. These modular designs are strategically designed to facilitate the remanufacturing process. Remanufactured parts do not have to be produced exclusively for their original purpose, it may make more sense to anticipate further use in other products with potentially fewer or different requirements. This could also increase the industry's commitment to sustainable practices and resource efficiency.

Outlook for the circular economy

The future of remanufacturing will be characterized by an increase in available components for recycling, creating the conditions for improved scalability. A notable example of this trend is BASF's ambition to remanufacture batteries for Iveco e-trucks, as highlighted in the recent announcement of the collaboration. In anticipation of a growing customer base, BASF is in a position not only to increase productivity, but also to continuously refine and develop remanufacturing processes.

At the same time, Renault has proven to be a pioneer in the automotive sector and has two dedicated centers of excellence for circular economy.

Looking to the future, a collaborative marketplace, possibly promoted by the EU, is a crucial step to advance remanufacturing practices. Platforms such as the EU-coordinated guide.digiprime.eu could play a crucial role by not only fostering collaboration but also providing a comprehensive overview of remanufactured parts, thus contributing to greater transparency and widespread adoption of sustainable practices in the automotive industry.

If you want to learn more about the circular economy, download this Use Case:

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach