Understand Why Production Planning Needs Specialized Solutions

Ute Strohmaier - March 19, 2024

In the dynamic landscape of manufacturing, the process of planning orders into production is not just a routine task but a pivotal aspect that can significantly impact the efficiency and productivity of a company. From medium-term planning spanning several months to short-term sequencing into individual production lots, manufacturers strive to optimize their resources and capacities to achieve the best possible utilization. This optimization journey involves various elements such as grouping operations, selecting appropriate batch sizes, and embracing Advanced Planning and Scheduling (APS) solutions. Let's delve deeper into these crucial components.

Understanding Sequencing in Production Planning

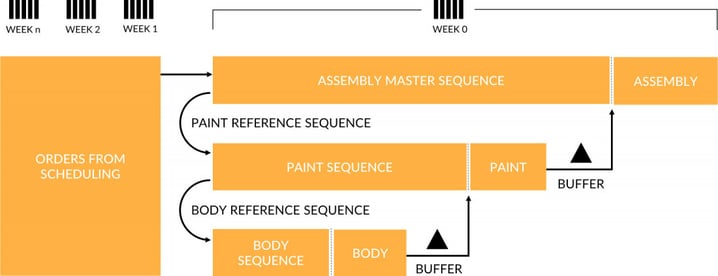

In industries like automotive manufacturing, where numerous production steps with different variants exist, sequencing plays a vital role. The goal is to minimize unproductive times such as cleaning or setup, thereby enhancing productivity and yield. Sequencing involves grouping production operations into lots and arranging them based on productivity and priority, a technique also known as pearl chaining. However, choosing the right batch size is equally essential. It's a delicate balance between adhering to lean principles by producing small quantities in chronological order to reduce inventory and fulfilling productivity goals by opting for longer production runs.

The Need for an APS Solution

As manufacturing complexities grow, the need for robust APS solutions becomes increasingly apparent. These solutions encompass long-term, mid-term, and short-term order planning while considering internal constraints and resource limitations. They bridge the gap between supply chain planning and execution, ensuring seamless data transfer and decision support. In today's landscape, OEM planners confront various challenges, including global component strategies, just-in-time production, increased product variety, and supply chain complexities. APS solutions emerge as indispensable tools to navigate these challenges effectively.

Why Order Sequencing Matters

In environments marked by fluctuations and changes, sequencing emerges as a crucial aspect of production planning. With the ability to run sequencing scenarios multiple times a day, manufacturers can ensure optimal planning even in dynamic conditions. Flexible rescheduling facilitated by sequencing solutions with optimization algorithms simplifies planning and enables rapid adjustments. Optimal Order Sequencing not only reduces lead times but also minimizes work-in-progress inventory, leading to enhanced operational efficiency.

Must-Have Features of APS Solutions

When considering APS solutions, several key features stand out as indispensable. Real-time capabilities ensure that all departments have access to the latest information, facilitating proactive decision-making. Order Slotting combined with Order Sequencing mitigates risks of downtime and inefficiencies. Modular implementation allows for flexibility and scalability, ensuring that the solution can adapt to evolving needs without significant disruptions. A clear user experience and connectivity with other systems enhance usability and data integrity, essential for effective planning.

Integration is crucial in the realm of production planning because it facilitates the necessary communication for effective decision-making. Without proper integration among systems, obtaining the essential information for accurate planning decisions becomes challenging. When your APS solution is seamlessly integrated with your ERP/MES, data can be shared swiftly and efficiently, ensuring that you always have the relevant information at your fingertips. This integration significantly reduces the risk of duplicated or inconsistent data, thereby enhancing the accuracy of the information available and enabling better planning decisions. Additionally, cloud-native solutions emerge as the answer to modern production planning challenges. The availability of Supply Chain Planning and APS Solutions in the cloud enables access from any location at any time, empowering production planners to respond promptly to changes and remain aligned with fluctuating market trends. With state-of-the-art, composable cloud services, additional services for additional needs can be implemented quickly and efficiently, ensuring adaptability and agility in the face of evolving production requirements.

Conclusion

In the ever-evolving landscape of manufacturing, production planning emerges as a critical function for optimizing resources, enhancing efficiency, and meeting customer demands. From sequencing production operations to embracing Advanced Planning and Scheduling solutions, manufacturers navigate a complex terrain filled with challenges and opportunities. By leveraging the right tools and strategies, companies can streamline their production processes, minimize disruptions, and pave the way for a more agile and responsive manufacturing ecosystem. In a world where agility and efficiency are paramount, mastering production planning is key to staying ahead in the competitive manufacturing landscape.

If you want to learn more get your Guide to Production Planning.

In this Guide you will learn:

-

How to build resilience

-

How to increase efficiency

-

How to use integrated APS planning services for production planning

-

What must-have features of an APS solution you need

-

Which KPI’s you can expect

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers