How to improve your Supply Chain Management: The Power of Control Towers

Ute Strohmaier - January 09, 2024

In today's dynamic business landscape, achieving transparency across supply chains is a top priority for companies, from order call-offs for manufacturing plants to delivery and the corresponding service provider invoicing. Planners and supply chain managers strive to control the flow of both transportation and information, including processes involving various partners in the supply chain. The key to resolving issues before they become problems and securing a reliable supply chain lies in utilizing a Control Tower. But what exactly does that entail?

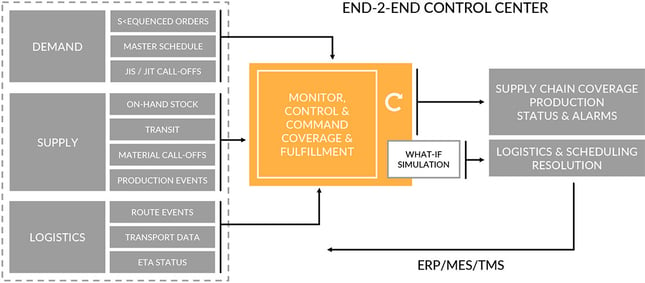

A Supply Chain Control Tower serves as an operational framework for capturing and utilizing a plethora of data. It provides a functional model for enhanced visibility, predictions, and predominantly area-specific, short- and medium-term, sometimes automated decision-making. Let's delve into the reasons why incorporating a Control Tower into your supply chain management strategy can lead to unprecedented efficiency.

Consider a manufacturer tasked with managing regular inbound flows to ensure a continuous supply of materials for production. Dealing with diverse products with thousands of components can pose a highly complex challenge. To address this, the manufacturer employs a cloud platform that automates quantity reconciliations and monitors the status of orders and deliveries. A "Control Tower" intervenes during system events, triggering alerts based on complete digitization and automation of the entire process chain:

-

Production order requests

-

Notification to the supplier, considering transit times, weekends, and holidays

-

Commissioning the transport service provider

-

Delivery to the production facility

-

Confirmation of timely delivery

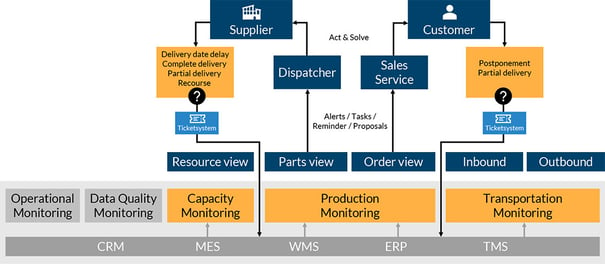

Any temporal discrepancies and corresponding quantities are escalated to an operational Control Tower with a ticketing system. The participants in the supply chain process can take necessary actions when alerts occur and interact with each other. For instance, a dispatcher working in the supply view receives a notification and creates a task in the ticketing system to "inform the supplier." If there's no response, the dispatcher receives a reminder and contacts the supplier (inquiring about part availability, partial delivery possibilities, potential recourse claims). Alternatively, the system suggests another supplier to secure material procurement. Once the task is resolved, the Control Tower changes the alert from red to green in the visualization. The sales person meanwhile works in the demand view of the system and to inform the customer or production plant about possible delays of the order delivery.

End-to-End Control Tower

Such an End-to-End Control Tower comprises views for:

-

Operational Monitoring

-

Data Quality Monitoring

-

Capacity Monitoring

-

Production Monitoring

-

Special Transport Management

The data sources include ERP, TMS, MES, and Big Data via interfaces to the Cloud Platform.

Unlike custom software solutions that require extensive maintenance and often still necessitate manual interventions, a Control Tower is a sustainable, reliable tool to support future improvement processes:

-

Active process control

-

Reduction of safety stocks

-

Transparency along the supply chain

flexis Real Time Monitoring

A cloud-based network architecture enables the integration of all involved partners and stakeholders, facilitating improvement measures across the entire supply chain. A holistic management process pursues clear, shared goals:

1. Monitoring Process Deviations

-

Providing disruption KPIs through event documentation

-

Automated alarm generation for deviations from the standard process along the process chain

-

Escalation mechanisms in disruption resolution

2. Standardization and Reporting

-

Standardized KPIs and reporting structures

-

Documentation of analyses

-

Regular reporting

3. Shared Improvement Process

-

Stabilizing the entire supply chain by sustainably addressing recurring error patterns

In conclusion, implementing a Control Tower in your supply chain management strategy isn't just a technological upgrade – it's a fundamental step towards enhanced efficiency, proactive issue resolution, and a more resilient and transparent supply chain.

If you want to learn more get your Guide to Multi Dimension Monitoring

In this Guide you will learn:

-

The Advantages of Multi Dimension Monitoring

-

Perspectives from a production or a transport point of view

-

Potentials for Planners and Dispatchers

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach