Preparing For Freight Volatility: 6 Steps You Can Take Now

Keith LaBotz - July 06, 2023

2023 is a year of significant changes for the transportation industry, with shipping demand and carrier capacity rebalanced after two years of scarcity and bottlenecks. However, volatility will return, and supply chains need a new solution to mitigate new troubles ahead.

Digitalization advanced significantly since 2020, when the last round of volatility hit, introducing a new problem. As integration increases across supply chains, the effects of transportation volatility spread faster. It’s a digital problem requiring a digital solution, in this case, digital collaboration between carriers and shippers.

Why is this important for supply chains now? Key indicators are signaling trouble ahead for transportation. The return of volatile freight markets appears imminent, but digital collaboration between shippers and carriers is rare.

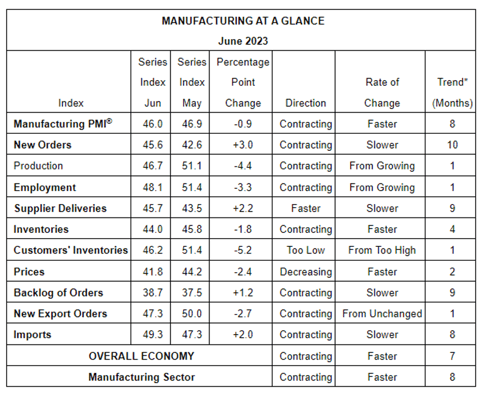

The latest numbers from the Institute of Supply Chain Management report the manufacturing sector in the US contracted in June for the eighth consecutive month.

Macroeconomic trends are affecting freight markets, and carriers are well advised to prepare accordingly. The following six steps will improve your company’s profitability and put it on a fast track to collaborative transportation.

1. Base Partnerships on Continuous Improvement

A pragmatic definition of supply chain collaboration is two partners engaging in continuous improvement to achieve common objectives. It requires an investment of time and technology from both parties in a digital supply chain, and that won’t happen without establishing trust.

Digital solutions facilitate trust-building by enabling transparency in the business process and producing measurable results.

For example, a shipper using a Transportation Planning solution to improve shipment forecasting can share the data with carriers, helping them utilize resources more effectively. A carrier benefits from this visibility, will value the partnership, and, through practice, learns to trust the shipper’s business process.

2. Focus on Total Landed Cost

Focusing on Total Landed Cost (TLC) instead of shipping charges provides more accurate management of delivery costs. Carrier pricing is only one cost factor of TLC, and the goal should be minimizing the total cost for each company.

The efficiency of supply chain processes varies between shippers and carriers, and taking a holistic view of the costs is vital to optimizing the overall business process. These costs are overlooked when attention is on freight rates, which come at the expense of the carrier and shipper.

Productivity solutions that enable visibility to TLC allow partners to identify and prioritize mutually beneficial improvements. For example, a carrier using a capable Vehicle Routing and Scheduling (VRS) solution to optimize its fleet operation can account for and control costs at every turn.

Likewise, a shipper using a Transportation Planning and Scheduling solution capable of performing what-if analysis can assess the impact of changing various aspects of the business process. The ability to measure how transportation decisions affect TLC allows both partners to focus on the optimal outcome instead of price.

3. Embrace Advanced Supply Chain Planning

Advanced supply chain planning with a holistic approach to optimization will have accurate forecasting, costing, and operational agility as its foundation. Carriers and shippers can share operational data and insights based on current conditions, allowing plans to adjust as conditions change.

4. Ditch the Annual Bid Process

The traditional annual bid process is incompatible with long-term collaboration in a digital supply chain. Win-win negotiations promote the interests of both parties and in a volatile market, companies need partners committed to their interests more than ever.

In contrast, scarcity tactics drive down prices in the bid process, breed mistrust, and inhibit parties from investing in each other.

The alternative is dynamic pricing models that rely on real-time visibility of supply chain processes. It’s another application of advanced supply chain planning. Consider it collaborative transportation planning with agreed-upon pricing parameters built into the model.

5. Share Data In Real Time: Use the Cloud

Sharing data is essential for supply chain optimization; cloud solutions make this easier. They also ensure scalability for supporting unexpected swings in demand and capacity, reducing the risk of system constraints. Volatility can return anytime, and time is of the essence - cloud solutions are the fast track to digital collaboration.

6. Prioritize Agile Logistics

Shippers and carriers must prioritize agile logistics processes so planning and execution can adjust as conditions change in a volatile market. Investing in technologies that increase agility facilitates real-time collaboration that can navigate the challenges of volatility.

Conclusion

Transportation volatility will return, and leading indicators suggest it may be imminent. Leveraging supply chain planning solutions to facilitate digital collaboration between carriers and shippers is vital for navigating freight troubles ahead.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach