Case Study: How One Wholesaler Won in the Last Mile

Keith LaBotz - June 08, 2023

A prominent book wholesaler providing customized fulfillment for retail bookstores wanted to maintain its high service standards when outsourcing final delivery to independent subcontractors. While the subcontractors are integral to the company’s strategy, they also hinder improvements in the last mile, presenting a dilemma.

The company precisely tailors its logistics process to the needs of each bookstore manager, and contracting final delivery to dedicated local representatives fosters greater collaboration and loyalty with customers. Open and transparent communications are vital to keeping customers apprised of delivery status and meeting expectations, making supply chain visibility a top priority.

Investing in digital logistics solutions allowed sharing of information between its 30 warehouses in Germany and Austria and 400 delivery vehicles with customers. While digitalization improved visibility, it also highlighted areas lacking - the final mile handled by subcontractors.

The Challenge

Subcontractor operations were beyond the reach of the shipper’s enterprise, preventing the company from realizing the full potential of its investment. As independent operators, each subcontractor chose their technology for managing deliveries. It would be difficult to improve the delivery experience and ensure consistency without standardizing the final delivery process for all subcontractors.

The challenge of integrating disparate business processes with its enterprise logistics system was enormous. Until a cost-effective solution could be found, a blindspot affecting the most crucial phase of transportation, the final mile, left several issues unresolved:

- Strategic Vulnerability The shipper’s strategic advantage hinged on providing customers with complete transparency to a reliable, customized delivery experience. But that requires control over the entire delivery process.

- Difficulty Making Continuous Improvement It's easier to identify process improvements with comprehensive logistics metrics, constraints, and costs.

- Inequitable Pricing Determining service value is complex and competitive benchmarking is only possible with standardized, complete, and accurate data. With this, less capable subcontractors with better negotiating skills may be overpaid, while the valuable ones are underpaid. The inequity can lead to losing the best subcontractors while incentivizing the least capable of remaining.

- Less than Optimal Performance With comprehensive supply chain visibility, logistics performance can be optimized. Without access to this data, delivery operations are exposed to risks from traffic congestion, ineffective subcontractor decisions, and vehicle conditions.

- Lower Level of Customer Service A subcontractor learns customer preferences when on site, and a knowledge gap of these preferences exists with the wholesaler. Without systematically capturing these requirements, the wholesaler must assume subcontractors are meeting them. Furthermore, this valuable information must be recovered with a change in subcontractors so service levels are maintained.

- Insufficient Risk Management Dependence on subcontractors for final deliveries posed risks to delivery continuity in the event of subcontractor-related issues. Lack of visibility to these risks and an inability to mitigate them left the wholesaler vulnerable to unexpected disruptions.

- Lack of Resilience The inability to manage risk and make process improvements jeopardizes business performance. A subcontractor going out of business or failing to perform could precipitate significant losses.

Solution Requirements

Overcoming these issues depended on gaining the full participation of subcontractors; it would need to improve the subcontractor’s business. The solution would need to extend the shipper's logistics management process to final delivery in a seamless manner, be easy to implement, cost-effective for subcontractors, and readily support the existing scenario:

- Retailer merchandise management systems place orders with the wholesaler by 6 p.m. each night for next-day fulfillment.

- The wholesaler uses its fleet to deliver orders from its warehouses to subcontractors.

- Subcontractors use their vehicles for final transportation to bookstores within their assigned territory.

- Subcontractors hold keys to the bookstores for after-hours restocking of designated locations, ensuring displays are orderly and meeting any other requirements specified on orders for each store.

The Solution: Collaborative Transportation

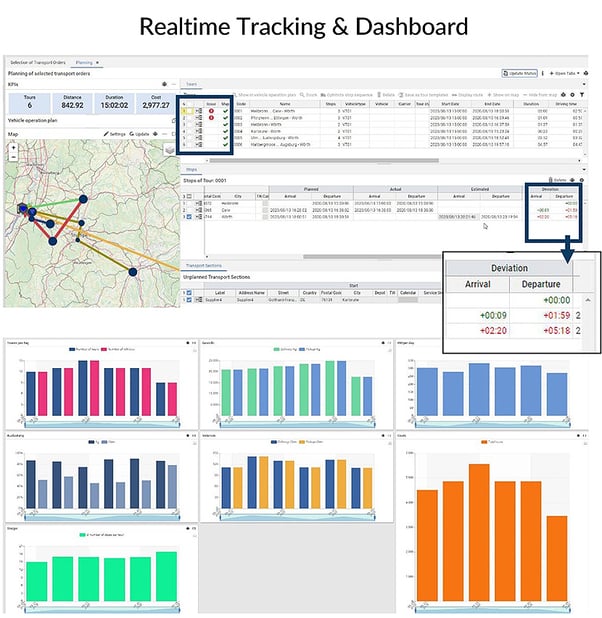

The company created a collaborative transportation solution by implementing an extended version of flexis SCM Vehicle Routing and Scheduling (VRS) as a SaaS (software as a service). Subcontractors could quickly increase operation efficiency, and the wholesaler was able to standardize the entire delivery process.

Because the cost is shared across multiple parties, the subscription is affordable for subcontractors of all sizes. The process improvements generate a positive ROI while resolving previously-mentioned challenges for the wholesaler and each subcontractor.

The wholesaler can integrate and manage the final mile as part of its enterprise transportation process, allowing process improvements that were previously impossible. Some of these improvements are included in the flexis solutions:

- Visibility of shipment and order details such as book titles, delivery time, location (e.g., where it is on the road or its shelf location in the bookstore), and operational data for every vehicle (including telematics data if provided).

- Optimization of routes to maximize profit, service quality, and sustainability.

- Route planning that considers seasonal retail fluctuations, holidays, and customer delivery windows.

- Scheduling considers site-specific delivery constraints like the number of trips and time required to cart books into a retail store, required elevator trips, distance from the loading zone, etc.

- Address verification and geocoding ensure error-free planning and navigation.

- Traffic patterns and temporary restrictions such as road works and roadblocks are avoided in the routing.

- A mobile driver app that automates tasks like capturing delivery receipt signatures, POD (proof of delivery) pictures, and driver notes.

- Real-time tracking of driver location from geo-positioning.

- Geofencing time stamps recording entry and exit entering and leaving delivery locations.

- Automatic and user-initiated planning supports adjustments in real-time when conditions change (e.g., use of alternative vehicles, responding to customer delays, etc.)

- Identification of optimization opportunities by detecting order consolidations, recurring disruptions, and routing changes due to changing conditions.

The Results

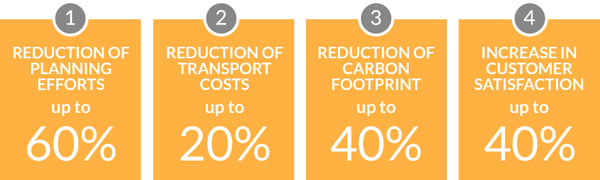

While optimization savings from SCM Vehicle Routing and Scheduling vary between companies and scenarios, falling within the average ranges noted below.

Conclusion

Leveraging a collaborative transportation solution in the cloud allows companies to standardize their delivery processes and gain a competitive edge. Enabling closer collaboration with supply chain partners makes it easier to exceed customer expectations while significantly improving logistics operations.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

Or do you want to learn more about the Gartner Top Trends in Strategic Supply Chain Technology 2023?

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach