The Top 10 Reasons for Shipping Delays and How to Stop Them

Keith LaBotz - November 17, 2022

Improving on-time delivery strengthens supply chains, increases profitability, and delivers better customer experiences. But probably not for the reasons you think.

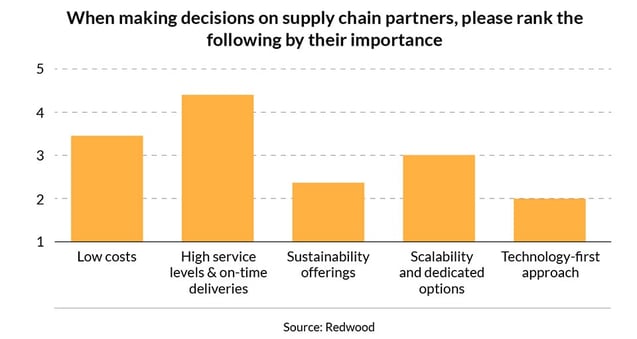

A recent survey ranks on-time delivery and high service levels as the most important qualities in a supply chain partner.

The demand for on-time delivery is not merely due to rising customer expectations for an Amazon-like delivery experience. There are also rising requirements from digital supply chain processes elevating on-time delivery to the top of the priority list.

Digitization Increases Demand for On-Time Delivery

Demand for on-time delivery will increase with digitization because it impacts the financial health of a digital supply chain:

- The primary mission of a supply chain is to deliver a product profitably, and the process involves parties transferring data, capital, and materials.

- Time is money, and speeding up these transfers has a financial impact on the participants:

- Quicker deliveries accelerate production, cash flow, and revenue.

- Deliveries made at the optimal time maximize efficiency and profits.

Why Shipments Are a Problem for Digital Supply Chains

Unlike the data and funds zipping through a digital supply chain, freight is not digital and that’s a problem. Shipments slow down the process, reducing efficiency and profits. Electronic funds and data transmit instantaneously through digital networks that are inexpensive and reliable. In comparison, shipments trail far behind and incur far more risks along the way:

-

Maritime, rail, air, and road transportation networks are full of potential obstacles that can delay shipments.

-

The transportation process is more dynamic and complicated to manage, requiring more decisions that can go wrong.

-

An unexpected disruption can delay transportation and quickly cascade into more significant problems.

- The above risks increase with supply chain volatility.

In summary, transportation is the weak link of a digital supply chain, and volatility jeopardizes the entire process. Volatility is here to stay with a global recession and geopolitical tensions dumping fuel onto a supply chain wildfire burning into its third year. What can your company do to minimize the risks and improve on-time performance?

The first step is to understand the most common causes of shipping delays, so. let’s begin by reviewing the top ten delays for delayed shipments and their solutions.

Let’s review the top ten delays for late shipments and their solutions.

Delay 1: Road Conditions

Problem: Traffic is the most significant contributor to late deliveries. Accidents, road construction, inclement weather, road debris, and rush-hour congestion can prevent vehicles from arriving as scheduled.

Solution: Transportation fleets should use a route optimization solution to optimize delivery routes around changing traffic conditions.

Companies should confirm that third-party transportation providers utilize route optimization software with this capability.

Delay 2: Ineffective Transportation Planning

Problem: Older transportation planning software considers a smaller range of parameters within the shipping operation instead of broader risks affecting the enterprise and its customers. These planning solutions leave shipments vulnerable to volatility, resulting in late deliveries.

Solution: Use a transportation planning solution that integrates supply chain planning and shipping execution to assess real-time risk across the supply chain.

- Real-time feedback between demand and transport planning, transportation execution, and transportation forecasting processes.

- A shipment planning window that covers several days forward.

Delay 3: Shipping Documentation

Problem: Every shipment requires complete, accurate documentation that meets specifications required by third parties handling and governing its transportation. Failure to meet these requirements will delay the shipment. For example, a single digit in the street address number off by one or a misspelled name can stop a shipment cold.

Solution: Use a multi-modal TMS process that automates all shipment planning and execution aspects with the following capabilities:

- Integration with order management, procurement, and supply chain optimization solutions.

- Support for third-party transportation carriers and digital market APIs.

- A native capability to generate a wide range of compliant shipping documents for small package, ocean, rail, LTL, and truckloads to support end-to-end compliance in a multi-modal delivery scenario.

- Carrier Documents and Data. Generating carrier-specific label formats like UPS and FedEx use the carrier’s unique algorithms to generate tracking numbers, service levels, and routing codes. Carrier-hosted APIs for shipping offers the easiest solution for compliance.

- Electronic manifest, bill of lading, or shipment tender records submitted to third-party transportation carriers at pickup. Enterprise systems must generate proprietary and regulatory data in compliance with each carrier’s format.

- Customer Documents and Data. Some customers require suppliers to generate a specific label and data format. Automotive, retail, and pharmaceutical companies generally mandate these in supplier compliance programs and dictate transportation carriers and terms.

- Government Documents and Data. Certain products, such as hazardous materials, cannot travel without the correct placards and declarations.

- Customs Documents and Data. International shipments are often delayed for Customs inspection when there’s a question about the completeness and accuracy of consignment, product, and harmonized tariff details on shipping documents. A TMS integrated with order fulfillment ensures shipment contents are consistent data on Customs Declarations, shipment labels, and carrier documents.

Delay 4: Lack of Visibility

Problem: You can’t fix a problem you can’t see, and lack of shipment visibility prevents mitigating delays. The earlier an exception is detected, the more options a company has to ensure shipments are delivered when expected.

Solution: A visibility platform like Project44 makes it easier to identify problems in transit and respond with corrective actions. However, it’s usually best to implement visibility after the TMS solution suggested for Delay # 3. Carriers and visibility platforms rely on shipping data from TMS systems to report shipment status.

Delay 5: Weather

Problem: According to the Federal Highway Administration (FHWA), weather causes 23% of all roadway delays, resulting in over 32 billion lost vehicle hours annually and costing trucking companies up to $3.5 billion.

Rain, freezing temperatures, high winds, and snow storms slow traffic and increase accidents. Extreme weather like severe thunderstorms sideline, divert, and damage trucks, ships, trains, and aircraft. Severe events are shorter-lived, unpredictable, very localized, and challenging to manage in logistics.

Solution: Use a technology like Weatheroptics to enhance the solution suggested for Delay #2 with hyperlocal forecasts at the street block level and alerts about developing weather risks.

- It adds weather risks into digital planning and execution processes that route and schedule pickup and deliveries.

- Detect severe weather risks affecting individual lanes, P&D routes, and vehicles.

- Enables transport operators to prepare or select equipment appropriate for weather conditions

- Allows rerouting of vehicles to minimize the impact of weather hazards.

Delay 6: Equipment Failure

Problem: Most truck failures occur in the brakes, tires, electrical systems, trailer couplings, and engines. The least expensive delivery service might be due to the use of older equipment and less investment in maintenance, increasing failure risk.

Solution: Choose carriers with better vehicle maintenance and safety records. US-based freight carriers registered with the DOT have CSA (Compliance, Safety, and Accountability) scores for maintenance and safety.

- Request each carrier to share their CSA BASIC scores for vehicle maintenance and unsafe driving.

- Choosing carriers with lower CSA scores to suffer fewer failures.

Delay 7: HOS Restrictions

Problem: Hours of Service (HOS) Restrictions limit truck drivers in the US to 14 hours of driving for each24 hour period, and the clock begins when a driver enters their tractor each morning. A driver stuck in traffic or experiencing an equipment failure clocks time without moving your shipment toward its destination.

Solution: Preventing Delays 1 - 6 allows drivers to cover more miles during working hours, keeping delivery schedules intact.

Delay 8: Insufficient Carrier Capacity

Problem: Securing carrier capacity can be challenging, and it will prevent a shipper from meeting delivery commitments. Freight markets are prone to volatility for multiple reasons. Poor visibility and forecasting of shipper demand and carrier capacity create volatility in individual marketplaces.

Solution: Integrate digital freight markets and brokerages into your company’s TMS. Choose vendors with APIs for posting loads, booking, tendering, and tracking.

Digital markets will expand with the digitization of the supply chain, making it easier to match demand with capacity and reducing volatility.

- Shipper forecasting, planning, and execution provide carriers with demand visibility and electronically book shipments.

- Due to improved demand visibility and accuracy, carriers can allocate capacity, price services, and commit to schedules.

- Market volatility decreases, resulting in fewer delays for shippers.

Following the solution for Delay #3 makes digital markets effortless, eliminating delays

Delay 9: Lost Freight

Problem: Carriers lose packages for various reasons, and the risk increases with the number of hub and vehicle transfers in the transportation network. These shipments seldom arrive on time if they escape OS&D hell.

Solution: Choose carriers using digital fleet management and TMS solutions with highly automated material handling. Look for transparent transportation networks that frequently scan shipments and report status to ensure accuracy and accountability. More scans mean greater visibility for your company and its customers. That will also help resolve Delay #4 on this list.

Delay 10. Failed Deliveries

Problem: When a customer is unavailable to receive a shipment, the reattempted delivery is usually late. Leaving these cases to customers to sort out delivery problems is common, but that forfeits an opportunity to provide on-time delivery and higher service levels.

Solution: Put yourself in the customer’s shoes and start thinking of your company’s shipping as your customers’ receiving process. Take ownership of the customer’s freight receipt with proactive monitoring and notifications of deliveries. Implementing solutions for Delays 1-9 will make it easier to automate email and text notifications like

- “Ship Notification” with shipment tracking link and ETA upon tendering freight.

- “Out for delivery” to remind the customer of imminent delivery and provide a convenient link to facilitate rescheduling if desired.

- “Missed delivery” with a link for contacting the carrier to reschedule.

Conclusion

Improving on-time delivery of shipments allows a company and its digital partners to realize the full potential of supply chain digitalization. It strengthens supply chains, increases profit, and delivers better customer experiences.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

Want to learn more about Multimodal Transportation?

Download our presentation and learn:

-

How can transports be planned quickly and yet flexible so that CO2 savings are verifiable?

-

How do you make optimal use of a multimodal transport network that maintains supply in both the short and long term?

-

How can you more easily realize a modal shift when disruptions occur? And how do you keep a grip on your CO2 emissions in doing so?

flexis and BigMile present a Use Case of a modal shift and show that network optimizations and sustainability often go hand in hand.

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers