Transport Optimization is Always the Best Response

Keith LaBotz - August 12, 2022

Risk and reward are proportionate; for supply chains, one process is about to get riskier and more rewarding.

Transportation is the most dynamic and volatile process in a supply chain, and volatility is expected to increase in the future. This presents a risk and an opportunity - it all depends on a company's response. Did you know there's a technology that provides the best response every time?

Two years of fighting a supply chain wildfire demonstrated how vital flexible planning is for supply chain health. Port congestion, capacity problems, and higher fuel prices quickly impact daily life, financial markets, and geopolitical stability. Companies with more agile transportation processes realized significant competitive advantages, which will continue.

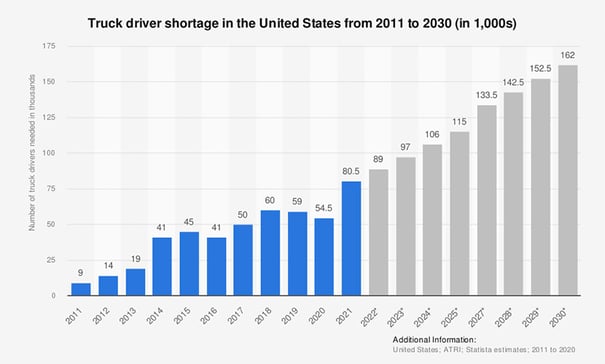

Source: Statista

Recent research projects a truck driver shortage in the United States, with an estimated 89,000 drivers needed this year and nearly doubling to 162,000 by 2030. Given this challenge, what should a company focus on?

The short answer is optimization. Carriers and shippers must make improvements that minimize transportation costs and ensure transportation capacity. That’s what transportation optimization does, and the rewards are significant:

- Shipping cost reductions up to 50%.

- Increased efficiency and expanded capacity for shippers and carriers.

- Higher levels of customer satisfaction.

What is Transportation Optimization?

- Transportation optimization analyzes shipping rates, lanes, business requirements, constraints, logistics tactics, and scenarios to determine the optimal delivery plan.

- The optimal plan meets all stakeholder expectations most effectively and efficiently. This includes maximizing profitability and customer satisfaction for every shipment and achieving sustainability goals.

Integrate S&OP, APS, Transportation

The first step of a journey is the most important one. For optimized transportation, the first step is integrating S&OP, APS, and transportation planning into a single, holistic process. This allows shipping requirements to render production and sales plans and vice-versa.

This step creates a foundation for assessing a more comprehensive range of tactics and scenarios. flexis products provide this, supplementing existing TMS planning with longer-range enterprise considerations that widen what-if analysis:

- Consolidating orders and shipments and more economical delivery methods.

- Altering S&OP and SP schedules for production and sales.

- Logistics strategies such as shipping from alternative points, consolidating inbound and outbound loads, intermodal transfers, and zone-skipping parcels.

Optimization must also incorporate execution-level details, such as route planning and vehicle scheduling to translate into an actionable plan. That's where carrier and routing optimizations enter the picture.

Carrier Optimization

Carrier optimization evaluates multiple constraints and business requirements to determine the best transportation mode, service level, and carrier for delivery. A company operating a private fleet can choose to use its vehicles or a third-party transportation provider for delivery.

Route Optimization

Shipments assigned for delivery by a corporate fleet undergo another series of optimizations for two types of vehicle routes: P&D (pickup and delivery) and linehaul. The end goal is an optimized delivery plan for each vehicle that maximizes sales revenue, operational efficiencies, customer satisfaction, sustainability, and profitability through an exhaustive analysis of parameters:

- Delivery commitment time

- Sequencing multi-stop pick-ups and deliveries

- Pick-up, delivery, and drop-off windows

- Labor requirements: loading and unloading vehicles

- Equipment requirements: refrigeration, air ride, flatbed, EV

- Handling: handling of fragile, high security, and hazardous freight

- Packaging Returns: if pallets and containers must be returned

- Vehicle profile: fuel economy, capacity, maximum weight limits

- Loading/ unloading: loading dock, roof clearance, liftgate, forklift

- Appointments: if a stop requires an appointment and when

- Road conditions: traffic, road closures, bridge clearance, weight limits

- Restrictions: No truck zones, one-way streets

- Driver Requirements: Driver must be available, have vehicle experience, and be familiar with the route. The route must be completed without exceeding the maximum driving hours stipulated in HOS regulations.

Linehaul Optimization

Linehaul transportation adds another layer to route optimization: freight transfers. Unlike P&D routes that vary with demand, linehaul is a recurring shipment following a predetermined route, usually moving inventory. The freight may be transferred to multiple delivery drivers, trucks, depots/terminals, hubs, distribution centers, warehouses, and sorting facilities.

The cost of each transfer can be accounted for when evaluating alternative options. However, there is a practical limit to how far this accounting goes, and few companies need to optimize beyond the initial leg of transportation.

Continuous Optimization is the Goal

So, you’ve integrated forecasting and planning, have an intelligent process that chooses the best carrier every time, and fully optimizes your in-house delivery fleet. Now what?

Continuously optimize the delivery plan. Transportation is the most dynamic process in the supply chain; conditions constantly change, especially in a volatile market. As supply chain digitalization and visibility progress, the ability to detect changes and optimize delivery plans will continuously improve.

Conclusion

As changes increase with volatility, companies with optimized transportation will realize more opportunities, and those without will be at greater risk. Transportation is the core of every supply chain, and optimizing it is always the best possible response to volatility.

flexis AG provides routing optimization solutions with S&OP, APS, and transportation planning integration.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

Want to learn more about Multimodal Transportation?

Download our presentation and learn:

-

How can transports be planned quickly and yet flexible so that CO2 savings are verifiable?

-

How do you make optimal use of a multimodal transport network that maintains supply in both the short and long term?

-

How can you more easily realize a modal shift when disruptions occur? And how do you keep a grip on your CO2 emissions in doing so?

flexis and BigMile present a Use Case of a modal shift and show that network optimizations and sustainability often go hand in hand.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach