The Freight Forwarder's Guide to Industry 4.0

Brian Hoey - June 12, 2018

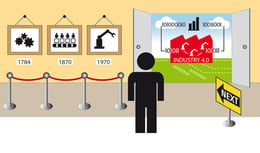

Though the industrial revolution was nominally about the introduction of steam powered machinery into factory production, its long-term effects are almost impossible to overstate. What began as an ingenious change to the inner workings of factories became a catalyst for widespread social and political change, arguably leading to the formation of modern capitalism and paving the way for a fundamental redefinition of people’s relationships to labor, their environments, and each other. Though the so-called second and third industrial revolutions were not quite as earth-shattering, they did stimulate the global spread of electricity and the internet, two technologies without which the modern world would be virtually unrecognizable.

Though the industrial revolution was nominally about the introduction of steam powered machinery into factory production, its long-term effects are almost impossible to overstate. What began as an ingenious change to the inner workings of factories became a catalyst for widespread social and political change, arguably leading to the formation of modern capitalism and paving the way for a fundamental redefinition of people’s relationships to labor, their environments, and each other. Though the so-called second and third industrial revolutions were not quite as earth-shattering, they did stimulate the global spread of electricity and the internet, two technologies without which the modern world would be virtually unrecognizable.

If Industry 4.0, which has been touted as the fourth industrial revolution, has an impact that is remotely comparable to those of its predecessors, then it’ll be remembered for a lot more than just powering the smart factory. Though it’s difficult to predict the global changes that these new technological systems will bring about, it’s safe to say that freight forwarders and shippers, who often work closely with manufacturers, will be some of the first to see these changes in action. As such, advanced preparation will be crucial.

What is Industry 4.0?

For those who might not know, or who might need a quick refresher, Industry 4.0 refers to the emerging trend of creating cyber-physical systems that promote machine-to-machine communication, primarily in industrial settings, i.e. the “smart factory.” The concept, whose name was coined by the German government in 2011, can encompass a whole host of different technologies, from cloud computing and machine learning to internet-of-things (IoT) sensors and autonomous machines, but at its core it promotes increased connectivity, visibility, and interoperability across value chains.

While this blending of the physical and digital worlds began as an industrial concept, use of the term has expanded to cover the creation of connected technological ecosystems elsewhere in the supply chain. Thus, these new and emerging systems can exist outside of factory floors. For those in the shipping trade, the rise of these systems will require not just a reckoning with changing client demands, but a reevaluation of your own IT infrastructure.

Pressure to Digitize

As alluded to in the last paragraph, perhaps the most important trend that shippers and freight forwarders will need to track as Industry 4.0 gains prevalence is digitization. As factories become increasingly digital, their needs and requirements are likely to change in ways that require higher degrees of digitization from their vendors and suppliers. If, for instance, a given business has automated (or even just digitized) its freight procurement process, that business is likely to express a natural preference for shippers that can integrate into those digital workflows by providing online quotations more or less instantaneously. By the same token, manufacturing businesses that utilize sales & operations execution (S&OE) workflows to manage potential disruptions may favor freight forwarding companies that can offer real-time tracking of orders and vehicles.

The examples above may potentially seem like instances of capriciousness or arbitrary preferences, but, if you think of the fourth industrial revolution as building data-driven ecosystems, it’s easy to understand why the operators of a smart factory would consider data visibility to be a top priority. At each step in the manufacturing process, data is collected, utilized, and shared in a highly visible manner; as additional high-quality information is integrated into the value chain, efficiency grows exponentially. By partnering with shippers or freight forwarders that provide the same level of transparency and connectivity, manufacturers grow their ecosystems and add additional value beyond bundling volumes and physical consolidation. By partnering with businesses that are unable to provide this level of visibility, they would lose out on this added value. More than that, the forwarding company in question, which should otherwise be cutting down the level of complexity involved in moving products long distances, would in fact be adding to the complexity via difficult integration with Industry 4.0 workflows.

Combating the Disparate Value Chain

While this post may have shippers feeling like the demands of these new technological realities will be onerous and difficult to grapple with, the reality of the situation is much less dire. Yes, increasing visibility and creating a more connected IT environment will be major hurdles for many in the shipping industry. Overcoming these hurdles, however, will offer not just competitive advantages in terms of finding clients, but exciting new opportunities to add value and bolster the efficiency and agility of your own operations.

For instance, as freight forwarding networks in the global supply chain becomes less concentrated, digital workflows can combat the new challenges that arise while helping to maintain visibility and cohesion. Again, shippers are hired in part because they’re able to decrease complexity for their clients, a task which becomes increasingly herculean as supply lines spread across the globe and the most common shipping routes lose ground to new paths with new challenges; what better way to provide value for your customers than by continuing to reduce this ever-increasing complexity through connected digital systems that turn byzantine global shipping realities into cohesive, comprehensible information?

Even looking beyond the question of visibility, adopting a digital supply chain offers shippers and freight forwarders the chance to leverage data into improved administration of core competencies. Not only will communication and collaboration with clients be made easier by shared or interoperable IT, but the bundling and consolidation of products and the optimization of capacity usage will be made more efficient by algorithms trained on digital representations of your value chain.

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers