Postmodern ERP: Not Just a Return to "Best of Breed"

Kristin Masters - November 17, 2016

-1.jpg?width=320&name=PostmodernERP%20(2)-1.jpg) How does your organization approach enterprise resource planning (ERP)? Not so long ago, ERP was completely absent from supply chain management strategy. Today in many organizations ERP dominates software solutions. But innovative supply chain leaders are adopting a new approach to ERP, one that goes far beyond "best of breed." This postmodern ERP fosters strategic collaboration between business and IT leaders and sets organizations on the path to thriving in the Industry 4.0 environment.

How does your organization approach enterprise resource planning (ERP)? Not so long ago, ERP was completely absent from supply chain management strategy. Today in many organizations ERP dominates software solutions. But innovative supply chain leaders are adopting a new approach to ERP, one that goes far beyond "best of breed." This postmodern ERP fosters strategic collaboration between business and IT leaders and sets organizations on the path to thriving in the Industry 4.0 environment.

A Brief History of ERP

The introduction of computer technology in the late 1960's and 1970's brought a fundamental shift to supply chain management. Activities that were once done manually could now be done by machine, and enthusiasm for automation swept the manufacturing industry. As software solutions became more readily available over the next two decades, supply chain managers increasingly adopted what's now known as the "best of breed approach." This method is characterized by the practice of selecting the "best" individual software solution for each business application or use area.

Even casual software users today can probably identify the primary drawback of the "best of breed" method: it fails to account for the need to integrate systems. Businesses that used the best of breed approach found themselves with a hodgepodge of software solutions that did little or nothing to support the overall business strategy:

- ERP was virtually nonexistent, leading to unseen, unmeasured costs and missed profit opportunties.

- IT leaders spent most of their time on tactical integration, rather than strategic planning. Most integration was point-to-point, rather than end-to-end, and manual intervention was often necessary.

- "Shadow IT," that is IT that is purchased outside the knowledge and oversight of the IT department, emerged as people simply made their own software and IT decisions.

As a response to these shortcomings, the 1990's saw a techonological swing in the opposite direction: the rise of the monolithic ERP, also known as the modern ERP. The modern ERP model used one ERP vendor solution, a "suite of suites" for all business applications. There was little to no use or integration of outside software, and IT held tight control over all software systems and solutions. However, the modern ERP had its own drawbacks:

- Although ERP gained necessary visibility, it was also tied to a cumbersome system that could not be easily updated as technology evolved.

- Casual users were often turned off by the modern ERP interface, resulting in lower adoption rates.

- IT leaders were often cut out of IT decisions, which were made by whoever had funds and authority to make purchases.

- Shadow IT persisted, as the modern ERP was often not nimble enough to offer tailored or specialized applications.

In recent years, supply chain management and IT leaders have noted a shift away from modern ERP, and they fear a return to "best of breed" tactics. This isn't an unreasonable concern given the proliferation of SaaS solutions and choices.

Postmodern ERP Offers the "Best of Both"

But the new phase of ERP isn't a complete return to "best of breed." Instead, it's a hybrid of the modern ERP and the "best of breed" approach, taking the best parts of each. Postmodern ERP has recently emerged as an ideal strategy, blending the specialization available through "best of breed" with the consistency and strategic capacity of modern ERP.

Postmodern ERP is like "best of both." This model uses a core ERP solution, bringing operation efficiency and business standardization. The core ERP is supplemented and complemented by specialized solutions, which are usually accessed either through the cloud or via business process outsourcers that can add value through innovation, differentiation and user-centered design.

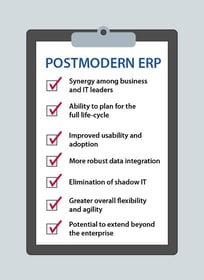

Postmodern ERP offers several key benefits that impact not only supply chain leaders but the organization as a whole:

- Synergy among business and IT leaders: Postmodern ERP is fundamentally different because it promotes collaboration between IT and the rest of the organization. Business and IT leaders work together to ensure that any software solutions support the overall business strategy.

- Ability to plan for the full life-cycle: A hybrid approach to ERP allows IT to plan ahead, creating timelines and key milestones grounded in capability needs. Solutions can be regularly evaluated and updated or replaced less disruptively, and as needed.

- Improved usability and adoption: Most casual users prefer an app-like interface and cloud-based services, which postmodern ERP can easily offer. This leads to increased user adoption and satisfaction, smoothing daily business processes.

- More robust data integration: Because the postmodern ERP brings together a wide variety of connected technologies, data and processes are much more fully integrated in the end-to-end system. This offers incredible new potention for S&OP and S&OE.

- Elimination of shadow IT: Because the postmodern ERP accommodates the use of specialized solutions, individual users can work with IT to obtain the technological tools they need, rather than "going rogue." This means that IT leaders can devote more time to strategic end-to-end integration, instead of struggling to identify unauthorized, unintegrated solutions.

- Greater overall flexibilty and agility: Adopting cloud-based specialist applications allows organizations to leverage upgrades provided by vendors, which often give users more ability to configure changes as they desire.

- Potential to extend beyond the enterprise: Postmodern ERP creates a sort of "value chain" that can interact with systems outside the enterprise. In the era of Industry 4.0, this is a particularly attractive feature because it means the supply chain can essentially interact with suppliers and customers, via specialized applications.

The manufacturing industry continues to evolve, and adoption of postmodern ERP offers considerable advantages as a supply chain management strategy. The key is collaboration between business leaders and IT specialists to ensure strategic implementation.

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers