Digital Manufacturers: What to Look for in a 3PL

Brian Hoey - November 27, 2018

Let’s say your manufacturing outfit is looking to hire a new employee, and you’re tasked with creating the job listing. What are you likely to ask for in your potential new hires? Depending on what type of IT environment your business runs on, you might require that they be familiar with a certain software or suite of software products, so that they can easily assimilate into your existing workflows. You might also ask for references from previous employers, so that you can be sure that they don’t present any obvious red flags. Going a little bit deeper, you might make a point of searching for employees who exhibit the potential to learn and grow, i.e. people who can potentially take on more responsibility as they go forward, helping your business to grow and adapt over time.

Let’s say your manufacturing outfit is looking to hire a new employee, and you’re tasked with creating the job listing. What are you likely to ask for in your potential new hires? Depending on what type of IT environment your business runs on, you might require that they be familiar with a certain software or suite of software products, so that they can easily assimilate into your existing workflows. You might also ask for references from previous employers, so that you can be sure that they don’t present any obvious red flags. Going a little bit deeper, you might make a point of searching for employees who exhibit the potential to learn and grow, i.e. people who can potentially take on more responsibility as they go forward, helping your business to grow and adapt over time.

As it is with employees, so should it be with 3PLs (or 3rd party logistics-providers). If you’re entrusting your company’s shipping, freight forwarding, cross-docking, and potentially even warehousing to another company, you need to be just as stringent in your requirements. In fact, you need to be just as stringent about many of the same requirements. What exactly do we mean by this? Read on to find out!

IT Integration

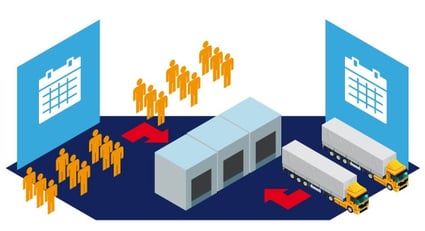

Just as your ideal new hire would already be familiar with your company’s preferred suite of software solutions, any 3PL you decide to work with should be able to offer integration with your existing IT infrastructure. If you're working in an Industry 4.0 environment, for instance, you should be striving for Logistics 4.0-enabled partners when it comes to logistics processes. This means that whatever operational data they collect should be easily available to you for planning and tracking purposes. Likewise, they should be able to work with and fit into any scheduling or reporting software that you currently use. Why is this so important? Imagine for a second that you hire a logistics provider that isn’t operating at the same level of digitization as your own organization. As your goods are being moved from your production facility to the third-party controlled warehouse to be bundled and eventually shipped, there is a massive power outage in and around the warehouse. Without functioning streetlights, traffic is at a standstill, and even once it starts to move again it’s not clear that inventory stocking will be able to continue at the warehouse during the outage. This is likely to have a significant negative impact on your ability to get your products to your customers on-time, but without IT integration you might not even know about the disruption until it was too late to take any mitigating actions.

If, conversely, you and your 3PL had some degree of shared IT infrastructure, you might receive an alert about the breakdown as soon as it occurred, so that you could make adjustments within your own production streams and other workflows to try and make sure that your customers were still getting the parts they needed when they needed them. By the same token, if there were a disruption on your end (say, a machine breakdown), a 3PL with a modicum of supply chain integration would be able to respond to the disruption more quickly (having been notified more quickly) and would be able to work with you more effectively to preserve value and get the right goods to your customers at the right time—using all of the information at their disposal about your own planned production streams, inventory levels, and capacity restrictions to help support an agile resolution to the problem.

Scalability

When we spoke of disruptions above, the underlying theme was that for a 3PL to truly provide value, they have to offer a certain degree of flexibility. We’ve seen how this plays out in the face of unexpected slowdowns and breakdowns, but what about things like demand changes or business growth? Put simply, any 3PL worth considering should be able to answer questions about what happens if you add new clients, or if your existing clients suddenly increase their order sizes, or if there is a general demand shift that could lead to meaningful operational changes. Under these circumstances, would you still be able to receive favorable rates and bundling options? Would the 3PL be able to increase their capacity to handle a sudden influx of orders without missing shipments? If your business is seasonal, is your 3PL prepared to handle potentially significant shifts in volume over the course of a given year? Naturally, the answers to these questions should really be “yes.” After all, a company that can’t support your attempts to scale up or down is only going to require you to put in more work in the long run, since you’ll likely have to change logistics-providers when your current one can no longer handle your needs. This, too, is in some ways question of IT integration, as a given company’s willingness and ability to integrate with your forecasting models and predictive analytics workflows can tell you a lot about their ability to grow with you.

References

Okay, this one is a little less technical than the last two. But it’s still an excellent indicator of how effective a given 3PL might be at meeting your company’s needs. Does the 3PL you’re considering have references specific to your industry? Have they worked with similar businesses before? What were the outcomes? If the 3PL were a potential employee, these would be the references from past employers—i.e. they would be a useful tool for finding out if the company or applicant can back up their claims. In this way, you can get a sense of how successful they’ve been at affecting IT integration in the past, how well they’ve worked with companies as they’ve grown or developed, and how they’ve responded to disruptions, hurdles, and other supply chain events. No business is perfect, but this will give you the chance to think about which value-added propositions are most important for you. Do you prioritize open and fast communication over the absolute highest on-time rate? Is minimizing total annual costs your most important goal, or would you sacrifice potential cost savings for being able to scale more easily in the future. These are questions that each business will have to answer individually, but those answers can and should guide you as you take references into account. Does the picture that’s being painted by the 3PLs references match what you were envisioning for your partnership? If so, you’ve found your 3PL. If not, you may need to head back to the drawing board.

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers