3 Tips For Greater Success With Supply Chain Agility

Keith LaBotz - July 14, 2022

Supply chains face a formidable array of threats, and recent studies indicate digitization efforts leave most companies more vulnerable than expected.

Most companies in the supply chain are seemingly doing everything right to protect themselves from supply chain volatility. Their top priority is resilience, and they invest in supply chain agility. Yet, more than half of all companies end up dissatisfied with the outcome and find themselves at a competitive disadvantage.

This is a newer development in supply chains rarely talked about. Understanding what’s happening can help companies avoid this widespread problem and gain an advantage only a minority of businesses enjoy.

Doing the Right Thing Can Go Wrong

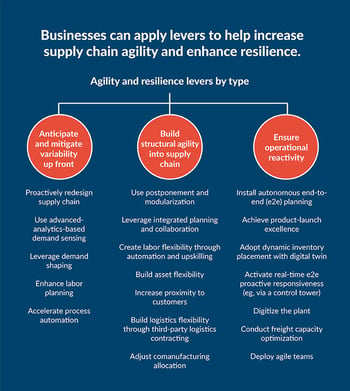

How can things go wrong when it appears a company is doing everything right to create enterprise agility? The answer becomes more apparent after considering the number of potential actions for increasing operational agility.

- Which of these deserves priority, and in what sequence?

- What process improvements are required to achieve desired results?

- Which technology partner best fits a company’s requirements, skills, and corporate culture?

There are multiple correct answers, and they vary based on a company’s current requirements. In turbulent times like the present, requirements can suddenly shift with changes in market conditions or business strategy.

It’s easy to find head down the wrong path with the wrong technology partner at any point in a transformational project and never realize the error. That’s what the majority of companies are doing as they pursue greater agility, and it's setting them up for a more severe problem in the future.

The Big Problem No One is Talking About

Organizations invested heavily in digital technologies over the past two years, intending to increase operational agility. Recent surveys indicate these projects failed to deliver promised results, leaving most companies less agile than expected.

- McKinsey reports that 70% of digital transformation projects are failures, and 17% of all IT projects are black swan events, an existential threat to the company.

- A new survey by Gartner, Inc. reveals that 56% of organizations report a high degree of regret over tech-related purchases over the past two years. Ouch!

The Emerging Agility Gap

A “high degree of regret” indicates unacceptable outcomes for 56% of these projects; these companies are more vulnerable to supply chain volatility than those with successful projects. With 70% of transformational projects failing, this number may be closer to 70% in practice.

On the bright side, 30% - 44% of companies are now able to withstand future supply chain volatility. They operate at lower cost and risk and maintain a 1 - 2 year development lead over the majority. These advantages remain intact even in a more favorable economic climate.

Supply Chains Will Divide Along the Gap

Survey results suggest a gap in capability and competitiveness between the minority of companies achieving agility goals and the majority that are not. Less agile enterprises are incapable of functioning at the level of more agile companies, and a supply chain network is constrained by the lowest common denominator. See where this is headed?

Supply chains will naturally realign around agility over time, leaving less agile businesses further behind. As businesses attract and seek out organizations with similar digital capabilities, a gap will develop along differences in operational agility.

A minority of companies are currently on the advantaged side of this agility gap, leaving the majority at a disadvantage. As digitization progresses, these differences will become more pronounced in supply chains, and companies will fall on either side of the gap.

Get on the Right Side of the Agility Gap

Getting on the right side of the agility gap requires understanding how the majority end up on the wrong side. You can read previous posts on improving the odds of success with supply chain process improvements.

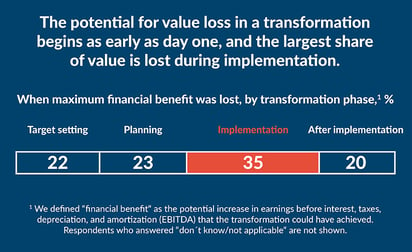

A McKinsey survey summarizes the phases in a transformation project and where efforts are most likely to get off track. The value loss indicates how far the outcome deviates from original expectations. Nearly half of the losses occur during target setting, and planning phases before process improvements even begin.

1. Start with Logistics Planning and Execution

The best starting point for process improvements is establishing tighter logistics planning and execution integration. Focusing agility around incoming and outgoing shipments makes it much easier to gain end-to-end visibility and collaboration in a supply chain. Everything else will naturally fall into place when a company begins building agility with logistics.

2. The Most Important Step

Most companies don’t know how and where to begin with digital transformation, so they naturally default to the familiar approach from the past. Digitization requires a holistic approach to work instead of rigid traditional supply chain management thinking. That’s why the majority of agility projects fail.

3. Select a Partner who fits best to your Requirements

The best way to prevent this is to find a qualified technology partner who can guide your company through each project phase. You can read more about this in last week's post.

Conclusion

There are many threats supply chains must contend with, and ironically, the biggest one may come from projects intending to protect them from external threats. This is a widespread problem affecting the majority of companies, and it is easily avoided with guidance.

flexis AG helps companies take the most important step toward agility, guiding them through each project phase to ensure success.

You want more information ?

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach