The Best Solution for Recession May Not Be What You Think

Keith LaBotz - July 08, 2022

What should a supply chain do to protect itself from an economic recession? Nothing. You’ll understand why in a moment.

Recessions are a necessary fact of life in market economies, purging supply chains of the weak and the wasteful. The only uncertainty is when a recession starts and how severe the purge will be.

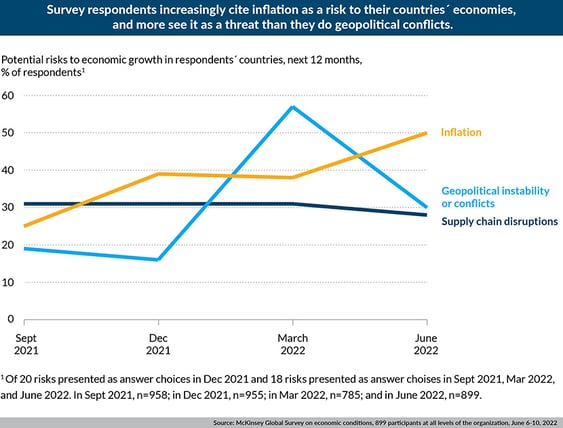

McKinsey’s Economic Conditions Outlook June 2022 reports growing pessimism about the global economy in the U.S. and EU for the last half of 2022. Inflation emerged in March 2021 and is now the top concern for respondents. High inflation tends to reduce demand, and it can worsen a recession, and could lead to stagflation.

The latest Logistics Managers’ Index paints the same picture in finer detail. The index is a monthly survey of supply chain logistics executives that gauges supply chain health.

One important measure is overall sentiment, and it declined 2.1 percent since May, hitting its lowest point since July 2020. Other indicators are flashing red, like increasing transportation and inventory levels, suggesting demand is dipping below forecasts.

The latest report notes, “The steep decline is reflective of what we have seen in the overall economy in the last three months, moving from the record-setting expansion of the last 18 months to the greatly subdued level of growth observed throughout Q2”.

Mark McDonald, Vice President and a Gartner Fellow within the Gartner for General Managers team, concludes we’re headed for a global recession. McDonald points to several factors and claims these will also produce greater turbulence over the next several years.

-

Rising interest rates.

-

Supply chain disruptions.

-

Tight labor markets.

-

Strong U.S. Dollar.

-

Lower stock market valuations.

-

Geopolitical conflicts and realignment of trading blocs.

-

Sociopolitical instability – particularly in the U.S.

Previous posts in this blog have echoed these same concerns over the past several months, likening the current situation to a wildfire that will eventually be extinguished by a global recession. None of these opinions that conclude a recession is inevitable are insightful, but merely state the obvious: what goes up must come down. What's not so obvious is the actions a company must take to prevent getting purged when the recession does it work.

Why Supply Chains Should Do Nothing

Back to the original question and the answer. There’s nothing a supply chain can do to protect itself from a recession because it's a network of autonomous entities. If the past two years proved anything, it’s how the network effect transfers volatility from one partner to the rest in a supply chain.

Concentrate on What You Can Control

A company can only control its internal processes, so building a more agile enterprise that adjusts planning and execution as conditions change is the most effective approach for managing volatility. Like accepting the inevitability of economic recession, a business can accept disruptions as a feature of supply chains.

The alternative, attempting to prevent supply chain disruptions at its source, requires the offending party to change their enterprise processes. Sounds good in theory, but in practice supply chain logistics is extremely fragmented at multiple levels, so gaining cooperation is difficult. Someone must solve the Supply Chain 4.0 Riddle for this dynamic to change.

Your Company Might Already Be On the Right Track and Not Know It

The good news is many companies are making process improvements to create a more agile enterprise. The supply chain wildfire over the past two years is the driver for many of these digitalization efforts as if Gartner is correct, by 2025 we can expect:

- Roughly 90% of companies will have budgeted improvements to increase resilience.

- More than 80% of organizations plan to develop digital ecosystems to support the most critical supply chain strategies - resilience, agility, and purpose-driven organizations.

Find a Qualified Technology Partner

Agility is ultimately about optimization, not fielding supply chain disruptions. Optimization evaluates the bigger picture, seeking the best possible outcome for any given scenario. Risk mitigation is a means to that.

A technology partner who is thinking about the bigger picture understands how supply chain agility forges a path to the end goal. Assuming you appreciate the implications here, there are several things to look for in a potential technology partner:

- Views agility as a prerequisite for large-scale optimization.

- Understanding the importance of synchronizing planning and execution in real-time.

- Provides a solution that will fully integrate supply chain planning and execution.

- Experience implementing end-to-end visibility of shipments moving thru the process is vital as well as changes to plans. You’re going to need a partner with a visibility platform.

- Knowledge of supply chain digital twins and guidance in capturing and standardizing data for predictive analytics, optimization scenarios, and development sandboxes.

- Depth of experience to see the bigger picture of optimization and the tiny details and process improvement must be addressed to achieve it.

Conclusion

A supply chain can do nothing to avoid economic recession and disruption. However, individual companies can protect themselves from these disruptions with a more agile enterprise. The easiest way for most companies to accomplish this is to find a qualified technology partner.

flexis AG meets all of the qualifications mentioned in this post and can help your company build an agile process to weather the coming recession.

You want more information ?

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach