What’s So Modern About Postmodern ERP

Nick Ostdick - November 09, 2017

.jpg?width=320&name=PostmodernERP%20(2).jpg) Buzzwords abound in today’s manufacturing and logistics industry. As technologies develop, emerge, and take hold, so does a new vocabulary companies must embrace in order to successfully leverage the concepts, principles, and philosophies of an ever-evolving business landscape. One such buzzword or topic of the day many planners and managers come in contact with yet fail to fully realize is postmodern ERP. Whether it’s because the lack of visibility surrounding these concepts or a failure to fully embrace them as part of lean manufacturing and supply chain management, postmodern ERP is perhaps one of the most least understood or actualized elements of manufacturing and supply logistics. Not only does postmodern ERP have the potential to transform a company’s manufacturing and supply logistics, but it’s a key element in cutting the complexity of global supply chain management and leveraging enhanced operational functionality.

Buzzwords abound in today’s manufacturing and logistics industry. As technologies develop, emerge, and take hold, so does a new vocabulary companies must embrace in order to successfully leverage the concepts, principles, and philosophies of an ever-evolving business landscape. One such buzzword or topic of the day many planners and managers come in contact with yet fail to fully realize is postmodern ERP. Whether it’s because the lack of visibility surrounding these concepts or a failure to fully embrace them as part of lean manufacturing and supply chain management, postmodern ERP is perhaps one of the most least understood or actualized elements of manufacturing and supply logistics. Not only does postmodern ERP have the potential to transform a company’s manufacturing and supply logistics, but it’s a key element in cutting the complexity of global supply chain management and leveraging enhanced operational functionality.

As something of a branch from enterprise resource planning (ERP), postmodern ERP takes the next step in helping companies across a number of critical functions in planning and production. But in furthering our understand of these buzzwords or key terms (like postmodern ERP), today’s manufacturing and logistics companies must ask themselves: What is so modern about postmodern ERP? What does postmodern ERP actually mean in terms of the day-to-day operations? What is the true value proposition of postmodern ERP in a global production and logistics network?

With these pressing questions in mind, let’s examine the history, definition, and key value of postmodern ERP to better understand and realize the real-world applications and benefits of this strategy and platform.

A postmodern ERP definition

To best define postmodern ERP, we must first briefly examine the history of ERP in general. The introduction of computer technology in the late 1960's and 1970's brought a fundamental shift to supply chain management. Activities that were once done manually could now be done by machine, and enthusiasm for automation swept the manufacturing industry. As software solutions became more readily available over the next two decades, supply chain managers increasingly adopted what's now known as the "best of breed approach."

Even casual software users today can probably identify the primary drawback of the "best of breed" method: it fails to account for the need to integrate systems. Businesses that used the best of breed approach found themselves with a hodgepodge of software solutions that did little or nothing to support the overall business strategy.

As a response to these shortcomings, the 1990's saw a technological swing in the opposite direction: the rise of the monolithic ERP, also known as the modern ERP. The modern ERP model used one ERP vendor solution, a "suite of suites" for all business applications. There was little to no use or integration of outside software, and IT held tight control over all software systems and solutions.

But the new phase of ERP isn't a complete return to "best of breed." Instead, it's a hybrid of the modern ERP and the "best of breed" approach, taking the best parts of each. Postmodern ERP has recently emerged as an ideal strategy, blending the specialization available through "best of breed" with the consistency and strategic capacity of modern ERP.

Postmodern ERP is like "best of both." This model uses a core ERP solution, bringing operation efficiency and business standardization. The core ERP is supplemented and complemented by specialized solutions, which are usually accessed either through the cloud or via business process outsourcers that can add value through innovation, differentiation and user-centered design.

The value of postmodern ERP

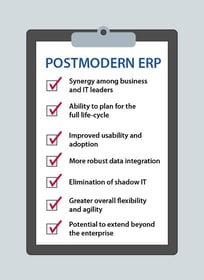

With a working definition and context of postmodern ERP at hand, we can now examine the key elements and overall value proposition of postmodern ERP in leveraging a more streamlined production and supply pipeline. Postmodern ERP provides a number of critical competitive advantages for planners and managers and for organizations in general. Some of these advantages include:

Synergy among business and IT leaders: Postmodern ERP is fundamentally different because it promotes collaboration between IT and the rest of the organization. Business and IT leaders work together to ensure that any software solutions support the overall business strategy.

Ability to plan for the full life-cycle: A hybrid approach to ERP allows IT to plan ahead, creating timelines and key milestones grounded in capability needs. Solutions can be regularly evaluated and updated or replaced less disruptively, and as needed.

Improved usability and adoption: Most casual users prefer an app-like interface and cloud-based services, which postmodern ERP can easily offer. This leads to increased user adoption and satisfaction, smoothing daily business processes.

More robust data integration: Because the postmodern ERP brings together a wide variety of connected technologies, data and processes are much more fully integrated in the end-to-end system. This offers incredible new potential for S&OP and S&OE.

Greater overall flexibility and agility: Adopting cloud-based specialist applications allows organizations to leverage upgrades provided by vendors, which often give users more ability to configure changes as they desire.

Potential to extend beyond the enterprise: Postmodern ERP creates a value chain that can interact with systems outside the enterprise. In the era of Industry 4.0, this is a particularly attractive feature because it means the supply chain can essentially interact with suppliers and customers, via specialized applications.

What’s perhaps most beneficial and influential about postmodern ERP is its ability to evolve and mature alongside the manufacturing industry. Postmodern ERP’s capacity for change and growth in alignment with a burgeoning global manufacturing network offers considerable advantages as a supply chain management strategy. Postmodern ERP’s capacity for forging connections between once disparate parts of the planning and production process cannot be understated in an increasingly connected industry.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach