Holistic Planning: Keys To Supply Chain Optimization

Keith LaBotz - May 25, 2023

As supply chains grow more dynamic from economic uncertainty and digitalization, warehouse agility emerges as a critical enabler of supply chain optimization.

The interplay between warehousing and supply chain optimization is strong and will become more pronounced as digitalization progresses. If there‘s any question about the significance of this relationship and why it deserves your attention, consider the port crisis two years ago.

Ocean ports, production sites, freight terminals, and warehouses control the flow of goods in supply chains. Disruptions in these operations quickly spill out into a supply chain, creating bottlenecks that ratchet up costs. The impact is identical for small warehouses and large ocean ports; the only difference is the scale of problems and how much attention they draw.

While the port crisis garnered global media coverage, most companies are unaware of ongoing disruptions caused by their warehousing operations. Several issues contribute to creating this blindspot:

-

Poor data visibility and rigid warehouse processes inhibit operational agility, making mitigating problems at their source difficult.

-

Consequences of shipping and receiving errors often appear as exceptions downstream, resulting in fixing visible issues instead of resolving their root cause in the warehouse.

-

Leases on warehouse facilities often run for three to ten years and can bind operations to rigid infrastructure undermining logistics flexibility.

Gaining the visibility needed to resolve these challenges begins with discarding the traditional view of warehousing as a storage function. Instead, its potential to create or prevent bottlenecks must be treated as a lever for improving supply chain performance.

Holistic planning is the key to unlocking warehouse efficiency and, subsequently, the full potential of supply chain planning. This article explains the symbiotic relationship between planning and agile warehousing.

Holistic Planning: The Key to Agile Warehousing

While most business enterprises use warehouse management software (WMS) and transportation management software (TMS) to manage logistics activities efficiently, supply chain optimization requires more than that.

WMS and TMS solutions must be guided toward supply chain optimization by a supply chain management (SCM) planning solution. That’s where holistic planning comes into the picture. It considers the impact of changes on production and distribution and formulates an updated plan accordingly in response to unexpected changes.

An SCM planning solution reveals more than an updated plan - it can also manage constraints, and with that knowledge, process improvements can be made to increase operational agility.

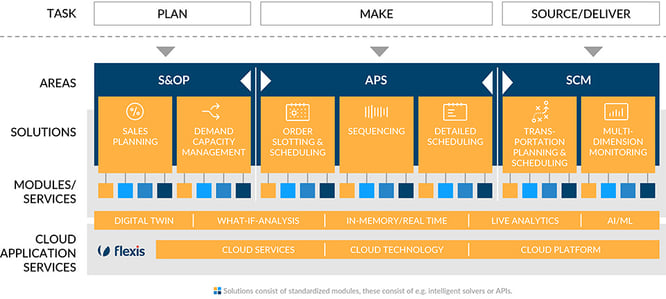

The most effective planning solutions integrate S&OP, APS, and SCM functions to optimize activities across a supply chain. The illustration above depicts the relationship between these activities, using a planning solution from flexis AG as an example. Optimizing SCM planning is the key to building an agile warehouse operation.

Agile Warehousing

Assuming process improvements revealed from planning are implemented, a more flexible warehouse operation results. The improvements support handling constraints and increase agility, enabling the planning solution to push the optimization envelope further.

Optimizing Production Planning

Advanced Planning and Scheduling (APS) facilitates real-time data exchange between sales and production, providing visibility into resource availability and material requirements. An APS solution can mediate demand output, synchronizing the production order process with a medium-term planning horizon. The following improvements are possible:

- Warehouse processes can be better aligned with production

- Existing TMS and WMS processes can prioritize activities so resources are utilized most effectively across a supply chain

- A comprehensive view of production, sales, and warehouse planning enables better decision-making, allowing process improvements that increase agility.

- Integrated analytics can be introduced to predict shipping and receiving disruptions.

- Expanded operational capacity through better utilization of enterprise resources and elimination of errors.

- Preventing over-committing and waste by assessing constraints such as labor availability, machine utilization, production schedules, and material requirements.

Optimizing Transportation Planning

An advanced Transportation Management Solution can automate route optimization, least-cost delivery selection, loading optimization, and shipment consolidation. These improvements align transportation activities so materials flow through production and distribution without disruption:

-

Streamlined shipment processing and minimized freight costs while improving on-time delivery.

-

More efficient warehouse workflow, higher profits, and increased customer satisfaction.

Improving Sales & Demand Planning

In addition to optimizing APS and transportation, implementing a Sales & Operations Plan (S&OP) ensures production and fulfillment commitments align with changing priorities, lead times, and capacity constraints. The impact on warehouse inventory, shipping, and supplier deliveries can be:

-

Improved Efficiency: Efficiency extends beyond the warehouse into the more significant supply chain through more effective decisions, better utilization of resources, and greater streamlining.

-

Reduced Costs: Eliminating bottlenecks and streamlining processes reduces labor and transportation costs across the supply chain.

-

Enhanced Customer Satisfaction: Quicker responses to volatility ensure timely delivery, improving customer satisfaction and loyalty.

-

Maximize Utilization of Resources: With an updated schedule, warehouse operations can fully utilize resources and inventory space whenever conditions change.

Improving Forecasting Accuracy

Accurate forecasting is essential to supply chain optimization, and by having implemented an S&OP process, you can significantly improve forecast accuracy for short, medium, and strategic planning.

-

Improved forecasting reduces excess inventory, lowers operating costs, and enhances resource allocation.

-

Accurate forecasting also helps synchronize demand and supply, minimizing stockouts and overstock situations.

-

More accurate inventory translates to fewer shipments and fulfillment errors.

-

Warehouse resources are utilized more effectively, increasing profits and customer loyalty.

Conclusion

As supply chains grow more dynamic, holistic planning will become vital, and warehouse agility will be critical for maximizing its potential. Likewise, implementing an integrated cloud-based planning solution that connects sales, production, and transportation planning is the key to building more agile warehousing operations.

If you want to learn more, download your guide to Supply Chain Resilience and the new Normal.

In this Guide you will learn:

-

Four steps to supply chain resilience

-

Use case of a large appliance manufacturer

Or do you want to learn more about the Gartner Top Trends in Strategic Supply Chain Technology 2023?

Get your download here:

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach