Can Industry 4.0 Prevent Supply Chain Disruptions?

Brian Hoey - January 03, 2019

Let’s say you’re trying to optimize your morning commute. Each day, you leave your house in the morning and walk to the train station, stopping by one of a few nearby coffee shops on the way to get your requisite dose of caffeine. This system works okay as it is, but because the coffee shops are sometimes crowded and the trains are sometimes late there is an overly-high level of variability in the length of time it takes to get from your front door to your office—meaning that you sometimes arrive earlier or later than you intended. To combat this variability, you download an app that gives you real-time notifications about train arrival times (so that you can adjust accordingly if a particular train is running late) and another app that approximates how crowded any given coffee shop is based on online check-ins. In this way, you can avoid the most crowded coffee shops and try to work around late trains, leading to a more stable commute time.

Let’s say you’re trying to optimize your morning commute. Each day, you leave your house in the morning and walk to the train station, stopping by one of a few nearby coffee shops on the way to get your requisite dose of caffeine. This system works okay as it is, but because the coffee shops are sometimes crowded and the trains are sometimes late there is an overly-high level of variability in the length of time it takes to get from your front door to your office—meaning that you sometimes arrive earlier or later than you intended. To combat this variability, you download an app that gives you real-time notifications about train arrival times (so that you can adjust accordingly if a particular train is running late) and another app that approximates how crowded any given coffee shop is based on online check-ins. In this way, you can avoid the most crowded coffee shops and try to work around late trains, leading to a more stable commute time.

This example might sound fairly trivial, but in point of fact it illustrates an important point about Industry 4.0. Namely, that when you have more information accessible to you, you can make better decisions and keep your plans on track more effectively. For a morning commuter, this can be a matter of a few saved minutes every day; but for a global manufacturer, small degrees of optimization can have a huge impact on your bottom line. If you can use Industry 4.0 processes to decrease disruptions within your supply chain, your entire business can move towards increased growth and profitability.

Inaccurate Forecasts

Many of the supply chain managers among you likely know first hand that some of the most dramatic disruptions in the supply chain result from inaccurate forecasts. A client suddenly increases or decreases their order from past years, and you’re left scrambling to produce more product or move more of your existing stock so that it doesn’t take up costly warehouse space. When companies rely on nothing put past demand to guide their visions of the future, situations like this arise all too frequently. How can Industry 4.0 help stave off these sorts of disruptions? Simply put, by reducing forecast error with advanced analytics.

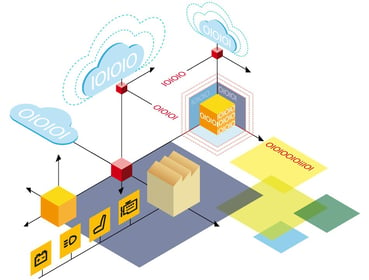

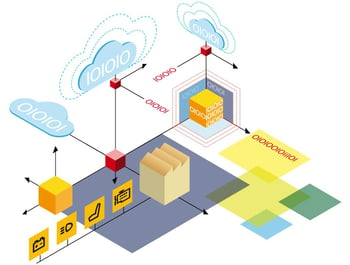

Essentially, Industry 4.0 systems are able to gather mission critical data from all corners of the value chain, centralize that data, and put it to work in advanced predictive and prescriptive algorithms. Thus, rather than simply relying on past demand levels to inform your expectations for the future, you’re able to rely on a smart, dynamic forecast that tracks real demand levels and extrapolates based on a wide array of different factors, from fuel prices to customer behavior. This enables you to adjust your production and shipping plans proactively, leading to fewer moments of disconnect between your expectations and reality.

Machine and Fleet Breakdowns

Another of the most common supply chain disruptions is machine or truck breakdowns. On some level, this is simply a fact of machinery—it sometimes stops working, either temporarily or for good. Just because every piece of equipment will eventually fall into disuse, however, doesn’t mean that there is nothing to be done. When it comes to factory floor machinery, for instance, Industry 4.0 systems (with their complex feedback loops between physical and digital workflows) can give you an account of whether a particular machine is being over- or under-utilized, meaning that you can proactively schedule maintenance or downtime to help stave off a potentially costly work stoppage. In fact, some factories have even begun to implement machine learning algorithms that identify the signs of an impending breakdown in advance and send alerts to production planners if a machine is exhibiting those signs.

The same processes can be applied to the trucks in which goods are eventually shipped. We’ll discuss fleet utilization and transport logistics in Industry 4.0 a little more in the next section, but suffice it to say that IoT devices, advanced telematics systems, and RFID chips make it possible not just to monitor a vehicle’s vital signs in real time, but to do so remotely from a central control tower. This means that transport planners can proactively reroute drivers to hubs or cross docks if it seems like their vehicle might need imminent maintenance—ensuring that your goods are kept moving even when your fleet isn’t.

Traffic and Weather Events

As promised, it’s time to dig a little deeper into transport logistics within an Industry 4.0 paradigm. Specifically, it’s time to think about the disruptions that are at once mundane and incredibly impactful within the context of the global supply chain: traffic and weather. Historically, static transportation routes have made it difficult for shipments of goods to avoid traffic and weather patterns that can cause costly and frequent delays. In an Industry 4.0 (or even Logistics 4.0) environment, things are much closer to the optimal morning commute described above: as traffic conditions change, transport planners can dynamically reroute their transports to avoid the worst conditions. Likewise, if a shipment is stuck in traffic or delayed by heavy rain or snow, planners will have enough visibility into their entire value chain to know whether or not another shipment can be rerouted to fulfill the delayed shipment’s orders, thereby preserving value for your customers.

These example represent just a few of the ways in which Industry 4.0 systems can stave off supply chain disruptions. In point of fact, it would be impossible to give an exhaustive list of such things. Why? Because Industry 4.0 doesn't refer to a discrete set of actions or technologies, but rather the creation of a more adaptive, responsive, and flexible value chain overall. Since most disruptions come from the unexpected, we can’t simply list them all out—but we can assure you that for almost any imaginable snafu, more knowledge, more visibility, and more flexibility will make it easier for you to respond effectively.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach