Can Digitization Reduce Supply Chain Disruptions?

Brian Hoey - February 07, 2019

In no particular order, the top supply chain disruptions include climate and weather events, forecasting errors, new trade regulations, oil and freight price fluctuations, machine and fleet breakdowns, and poor IT and technology integration, among others. As you peruse the list above, you might notice each of these disruptions can be put into one of two categories: fast or slow. Things like machine breakdowns and catastrophic weather can happen in the blink of an eye, and supply chain managers have to be prepared to preserve value via a backup plan. But other issues, like poor forecasts or integration issues, compound slowly over time—sometimes so slowly that it can be hard to identify the root cause of whatever difficulty your company is experiencing.

In no particular order, the top supply chain disruptions include climate and weather events, forecasting errors, new trade regulations, oil and freight price fluctuations, machine and fleet breakdowns, and poor IT and technology integration, among others. As you peruse the list above, you might notice each of these disruptions can be put into one of two categories: fast or slow. Things like machine breakdowns and catastrophic weather can happen in the blink of an eye, and supply chain managers have to be prepared to preserve value via a backup plan. But other issues, like poor forecasts or integration issues, compound slowly over time—sometimes so slowly that it can be hard to identify the root cause of whatever difficulty your company is experiencing.

Because disruptions are such an important topic in supply chain management, people sometimes have a tendency to paint with a broad brush, talking about all disruptions as if they were the same. By breaking them down into two categories in this way, we can be more precise in how we talk about them, just as we can be more precise in the questions that we ask. For instance: how can supply chain digitization effect disruptions, slow and fast alike?

Stemming the (Slow) Tide

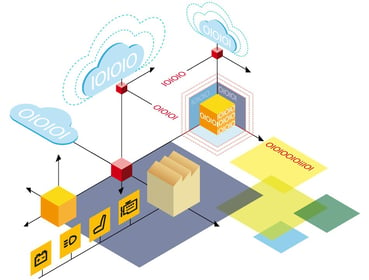

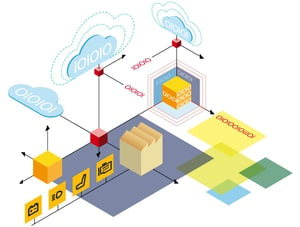

In a digital supply chain, the bulk of the processes that were once performed manually are instead done in a digital environment. This is made possible by the ever-increasing flow of digital information and data from every corner of the value chain, from factory floor machine data to demand and pricing information from up- and down-stream sources along the value chain. This transition to digital processes helps to bolster visibility and to add new opportunities for optimization and improved efficiency. How? By giving planners access to the information they need to make informed short-, mid-, and long-term decisions, while simultaneously giving them access to digital tools that can help them schedule production and transport plans more effectively.

On some level, it stands to reason that a smoother, more intelligently administered supply chain would be more resilient in the face of disruptions. This begins with the types of slow, creeping disruptions that we alluded to above. Forecast errors, for instance, tend to arise because of incomplete or outdated information, coupled with processes that can’t incorporate or adapt to new data. In a digital environment, this is much easier to avoid. Because demand information is being aggregated from numerous touchpoints on the supply chain, your (digital) demand forecasting models will have access to a critical mass of data; as new data comes in, those models can incorporate new information and display new expectations accordingly. Thus, rather than a static set of expectations that might become outdated fairly quickly, supply chain planners can adjust their plans as their future expectations evolve. In this way, the type of long-term disruptions that occur when expectations aren’t aligned with reality won’t have time to ferment. This means a decrease in the number of costly inventory overages and parts shortages, due to a closer alignment between real demand with production plans and inventory management.

The Need for Speed

We've dealt with slow disruptions, but what about the kinds of supply chain events that happen in the blink of an eye? Can supply chain digitization help to preserve value when a truck carrying an important shipment breaks down by the side of the road, or a machine on the factory floor suddenly stops working? As it happens, digitization can pave the way for more effective responses in these situations as well. How? By giving planners the tools and information they need to respond on the fly to emerging scenarios. Imagine that you’re working in a pre-digital environment and you get word that a truck has broken down and its shipment isn’t going to make it to its destination. Your options, in this scenario, might seem slim. The resources required to get the right shipment of goods to the customer or warehouse in a timely manner might still be out there, but it’s difficult to know without the level of visibility that’s only possible in digital environments. You might call various hubs and crossdocks within a small radius of the breakdown to find out what resources they can make available, but if it’s after business hours won't be able to help right away. As a result, you’re essentially stuck until you can gather more information, meaning that maintaining on-time delivery is unlikely.

In a digital environment, the very information that’s so hard to come by in the above scenario should be easily accessible. As you result, you should be able to assess your options immediately. If there’s a way to preserve value and maintain on-time deliveries, you’ll know about it, and you’ll be able to take advantage. In the case of other varieties of fast disruption, the intervention of a human planner might not be necessary at all. Unexpected traffic patterns, for instance, could easily have delayed shipments in the pre-digital era, but digitized route planning workflows (based on real-time traffic data) can automatically update route and tour structures on the fly in order to reflect changing realities—keeping shipments out of traffic jams in the process.

Digital Synergy

So far, we’ve seen the ways that a digital supply chain can make your business more resilient to both kinds of disruption, but we haven’t really emphasized is the extent to which these processes are two sides of the same coin. To wit, the respective short-term and long-term flexibility and adaptability that’s inherent to digital supply chains actually have a synergistic effect, mutually adding value to one another in such a way as to make digital value chains even more resilient. As an example of this phenomenon, we might take S&OE, or sales and operations execution, which is the process by which planners make adjustments for weekly and monthly fluctuations in demand levels while providing a real-time snapshot of demand for longer-term planners to leverage. In this instance, we see the way that digitally-bolstered responses to shorter term disruptions and potential disruptions actually inform longer term disruption resistance. Not only do short-term disruptions get addressed, they get addressed in such a way as to decrease the likelihood of slower disruptions emerging. As these slower disruptions are staved off more effectively, businesses are able to gain the added visibility and flexibility to respond to fast disruptions even more effectively. Thus, a virtuous circle of added value works its magic on your supply chain.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach