6 Things to Consider When Implementing an S&OP Solution

Robin Hornung - May 03, 2022

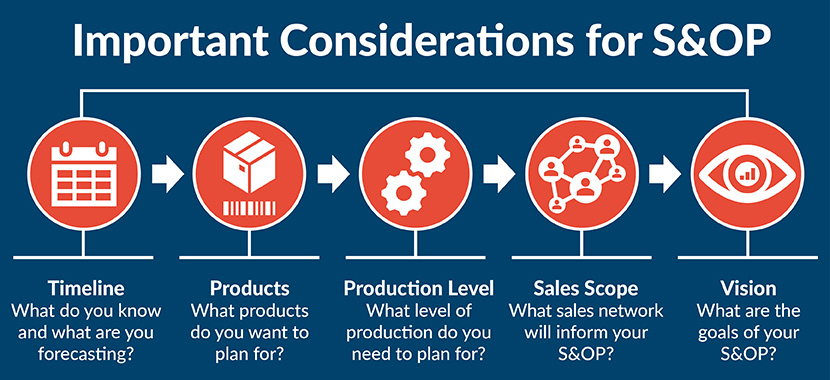

Theoretically, implementing S&OP can be a straightforward process to boost your company’s bottom line. But developing an effective S&OP solution requires careful consideration of your short- and long-term goals and communication across the entire enterprise. With multiple vendors now offering AI-enabled S&OP solutions, many companies are trying to navigate the transition from a legacy system to a dedicated software. Here are some important considerations to keep in mind when implementing a custom S&OP solution.

1. What is your S&OP timeline?

To start off, the first thing you need to consider is the scope of your time horizon. What historical data do you want to use to inform the software? How far do you need projections to be forecasted? Plus, what granularity will you require for this information? For example, do you need predictions on a monthly, quarterly, or yearly basis? All these considerations should inform the overall timeline of your S&OP solution.

2. What products do you want to include?

Depending on your company and industry, you likely won’t need all the products in your current production lines to develop a robust S&OP solution. But how do you figure out which products to include? In discussion with your S&OP vendor, an expert can help you determine the final number of products to optimize your S&OP configuration.

3. What production level do you need to plan for?

Your S&OP goals will also determine to what level you need to plan production. For example, do you need to plan to the plant or the production line level? You may need to consider critical machinery and suppliers that can impact production. One tip is to consider at what level you are already collecting information on output and production time. This can help inform the level for S&OP planning.

4. What strategy will be used to incorporate sales?

Expanding on production planning, you will then need to determine the level to which you will plan sales. Are you looking to plan by market, country, or region? One suggestion is to discuss your options with the S&OP vendor. An expert can help you clarify your vision for the modeled sales network that will inform the software. In general, there are two main strategies: plan centrally and monitor on an entity level or plan at an entity level and monitor centrally.

5. What is the broad scope of the S&OP solution?

Here is where you will take into consideration the process scope that will be covered by your custom solution. Are you hoping to just do production planning? Perhaps you want to include optimized transportation routes or intelligent inventory ordering? You can even design your S&OP solution to prioritize sustainability. For this stage, we recommend gaining inspiration through discussions with your internal teams and colleagues as well as your S&OP vendor.

6. What fine-tuning will you require?

Your previous five steps will inform the level of fine-tuning required for your S&OP solution. The final parameters will also be modified to fit the selected products and their planning scope to meet your overall company goals.

Complete Customization with flexis’ S&OP Solution

At each stage of the configuration process, flexis offers expert engagement to develop a custom plan for your S&OP process. The flexis solution uses AI to help create an intelligent S&OP solution to meet the needs of global enterprises in the modern age.

You want to learn more about S&OP solutions? Get your guide:

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers