5 Tips for Avoiding Supply Chain Disruptions

Brian Hoey - March 07, 2019

Often, when trying to advise their readers on the best ways to avoid supply chain disruptions, experts and other commentators will suggest increasing your buffer stock. No doubt this is effective when it comes to staving off shortages, but it’s still a deeply unsatisfying answer. Why? Because stockpiling goods is frequently costly, and doing so can bog down your operations in the long run. Sure, it can be useful insulation against the unexpected, but it’s also the antithesis of anything resembling an agile or lean supply chain.

Often, when trying to advise their readers on the best ways to avoid supply chain disruptions, experts and other commentators will suggest increasing your buffer stock. No doubt this is effective when it comes to staving off shortages, but it’s still a deeply unsatisfying answer. Why? Because stockpiling goods is frequently costly, and doing so can bog down your operations in the long run. Sure, it can be useful insulation against the unexpected, but it’s also the antithesis of anything resembling an agile or lean supply chain.

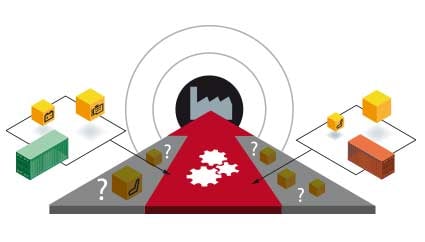

For supply chain managers who are hoping to maintain a certain degree of leanness, the trick is to find ways to mitigate disruptions without costly fortifications at every turn. This means finding ways to be smarter, and more proactive, rather than more defensive and reactive. What are some of those ways? Read on to find out!

1. Expect Disruptions

It might sound paradoxical, but the first step to avoiding disruptions is to know (and act on the fact) that it’s impossible to avoid all disruptions. It’s simply a fact of life in the supply chain management industry that sometimes things will go off the rails, and supply chain managers will have to scrap their plans and start again. Once you believe this, you can start to develop a more proactive mindset, seeking out areas of improvement and potential process changes to help make your operations more resilient when, not if, something goes wrong. More practically, it means that you can assign a point person for potential disruptions and create backup plans for likely scenarios. Obviously, if you could predict exactly what would happen in advance you really could eliminate disruptions, but you can still have a general outline for what will happen if a supplier cancels a shipment, if there’s a sudden price hike in raw materials, if customer demand experiences a huge dip or spike, etc.

2. Decentralize, Decentralize, Decentralize

Imagine a scenario: all of your stock is centralized in one warehouse, waiting to be earmarked for orders and loaded into trucks. Unexpectedly, there’s a massive power outage in the area, and none of your goods can be loaded in or out. There are shipments on the way to the warehouse, and scheduled outbound transports, all of which now have to be rerouted or stalled. To make matters worse, your computer systems were also affected by outage, meaning that the data a supply chain planner would need in order to try and salvage some value is suddenly inaccessible. Sound pretty dire, doesn’t it? The best way out of a situation like this is to never let it happen in the first place. How? By avoiding this kind of centralization in your value chain. Not only does it lead to data and decision-making silos, it also gives your supply chain almost no wiggle room when something goes wrong. This applies not just to inventory management but to decision-making more broadly. If your inventory had been spread across multiple warehouses and mission critical data had been available more widely, you might have been able to reroute your shipments more productively, using stock from other warehouses to fulfill orders in a comparatively timely way, while also receiving shipments at those other warehouses.

3. Increase Visibility

This tip dovetails nicely with the tip above. Why? Because in order to have robust, decentralized decision-making, you first need to make sure that each touch point on your value chain has access to data from every other touch point. Without this level of visibility, a planner outside the affected warehouse in the example above might have no way of knowing how many and which shipments were due to be received that day—and would thus have no way to reroute them. To speak more broadly, it’s impossible to respond effectively to an unexpected bottleneck or breakdown without a clear accounting of the resources at your disposal for dealing with the situation. Of course, this is easier said than done, but adopting a more cohesive IT infrastructure that promotes connectivity and helps to discourage silos can go a long way. The ultimate goal here is to be able to monitor supply chain activity in real time, in order to be able to identify potential disruptions early on and take immediate action to preserve value.

4. Integrate with Your Suppliers

Once you have a degree of IT integration that enables you to collect and access data from each point on your company’s supply chain, the next hurdle is to expand that visibility to your suppliers and to other operations up and downstream in the supply chain. The logic here is the same as the logic above: the stronger your understanding of your existing resources, the more easily you can see ways to leverage those resources when a crisis seems to be looming. More specifically, this would conceivably enable your organization to anticipate late deliveries or shortages on your suppliers’ parts much earlier on in the process. As a result, you would be better positioned to create a Plan B that either accounted for the parts shortage or found a secondary source. In this way, you stave off the larger negative impact to your sourcing, production, and transport workflows that would otherwise result.

5. Improve Your Forecasts

Okay, so you’ve planned for inevitable disruptions, decentralized your supply chain, and gained visibility across the value chain—you must be pretty well insulated against disruptions by now, right? To a large extent, yes. But that doesn’t mean there’s nothing else you can do to ward off the unexpected. If you’re already operating at a high degree of visibility, whatever data you’re collecting and storing could be leveraged into advanced analytics workflows to improve your forecasts. In general, disruptions happen because it’s impossible to predict the future. But in the modern era, advanced analytics algorithms have the power to extract insights from data that make the future, if not predictable, at least more predictable. Instead of basing your future plans solely on past events, you can use analytics processes to drive a more proactive planning process—one that anticipates future changes in demand levels, fuel prices, and other factors in a way that no human planner could realistically do. In this way, you make disruptions even more likely, thus keeping your supply chain smooth, agile, and profitable.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach