The Vital Role of Advanced Planning and Scheduling in Manufacturing Excellence

Ute Strohmaier - November 28, 2023

In the intricate world of large-scale manufacturing, the role of Advanced Planning and Scheduling (APS) emerges as both challenging and indispensable. At the heart of significant decision-making processes, APS involves aligning daily orders with Operations, Manufacturing, and Supply Chain plans in a dynamic field that requires constant adaptation.

The Complexity of APS

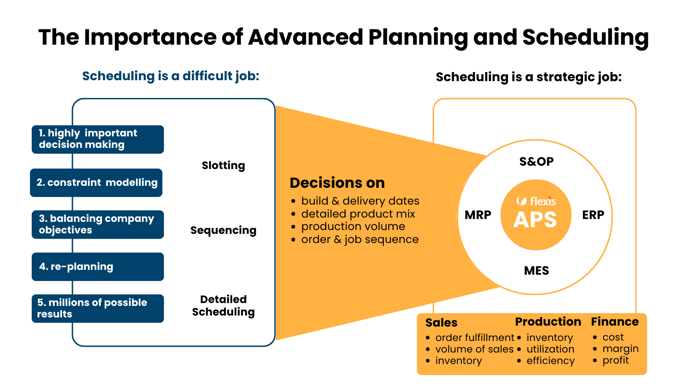

APS is no easy feat for several reasons. It involves managing the intricate complexity that comes with millions of possible results. Daily re-planning is essential, and decisions revolve around critical factors such as build and delivery dates, detailed product mix, production volume, and order and job sequence.

The journey in APS includes key components such as slotting, sequencing, and detailed scheduling. Slotting takes into account current production conditions before assigning delivery dates, sequencing optimizes production sequences based on existing orders, and detailed scheduling optimizes production programs while creating transparency for demand, resources, and capacities.

Scheduling as a Strategic Function

Scheduling is not just a daily operational task; it is a strategic function that directly impacts the quality and speed of production output. It plays a central role in the IT architecture, ensuring seamless integration and efficiency. Aligning scheduling with broader company strategies ensures coherence and effectiveness in achieving overarching goals.

flexis APS strategically integrates Manufacturing Execution Systems (MES), Material Requirements Planning (MRP), Enterprise Resource Planning (ERP), and Sales and Operations Planning (S&OP) to achieve various goals across different aspects of the manufacturing process.

The Importance of APS Solutions

A solution for order slotting and scheduling involves placing incoming orders into a production schedule. These solutions are tailored for shop floor-oriented manufacturing processes and are of great importance in the manufacturing industry. Schedulers are tasked with understanding production processes, modeling supply chain constraints, and balancing various company objectives.

flexis scheduling products influence crucial decisions, including when to build orders, how much to produce, and the detailed job sequence for production. The choice of an APS solution for scheduling is strategic, impacting operations planning, ERP data, downstream supplier schedules, quality, and manufacturing execution systems.

Evolving Trends in APS

The deployment of APS solutions has been evolving, with companies shifting to the cloud and using APS solutions as add-ons to their ERP systems. flexis delivers containerized software for cloud deployment, offering subscription models and expanding into the cloud-based service model.

Scheduling is extending further into the long-term horizon, with companies seeking high granularity in their long-term plans. No-touch transactions, where orders are placed autonomously with minimal human intervention, are becoming prevalent. This involves integrating man and machine workflows, with planners still playing a crucial role in optimizing schedules.

Flexible manufacturing processes are on the rise, requiring solutions that support N-tier scheduling and detailed scheduling. The shift to electric vehicles is also changing manufacturing processes and supply chains. IT efficiency and effectiveness are crucial considerations, leading companies to look for streamlined and cost-effective solutions. And, last but not least, software providers need to ensure that their products are ready for various cloud deployment strategies.

The Future of APS

The momentum of digital transformation is driving companies to seek technology-enabled solutions, and the role of a translator, bridging the gap between business and technology, becomes more important for a technology provider like flexis. Remaining competitive in the APS market involves continuously adapting to evolving customer requirements.

The impact of machine automation in scheduling is expected to grow, requiring the simplification and streamlining of products while retaining human intelligence for rule-setting. While machines will play a more substantial role in the scheduling process, human expertise is still necessary for defining the rules and constraints.

Looking ahead, the convergence of business and technology, coupled with the use of data, will help better understand patterns and optimize scheduling products. The future lies in their ability to adapt to changing customer needs, simplify the scheduling process, and leverage data to make intelligent decisions.

In conclusion, APS is not just a technical function within manufacturing but a strategic imperative that influences the efficiency, profitability, and adaptability of companies in a rapidly evolving landscape. As technology continues to advance, the key lies in the ability to embrace change, utilize data intelligently and respond flexibly to ever-changing demands.

If you want to learn more, download your guide to Transformation of Manufacturing Processes.

In this Guide you will learn:

-

Emerging Challenges in the Modern Truck/Automotive Industry

-

How Can Global Companies Adapt to These New Realities

-

How Decentralized Digital Systems Power Smarter Planning Processes

-

How flexis Can Support Flexible Supply Chain Transformation

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers