What You Need To Know About Mixed Fleets With EVs

Keith LaBotz - March 06, 2023

As electric vehicle (EV) affordability and performance increase, so do potential profitability and sustainability for transportation fleets.

Like everything else supply chain, realizing those gains requires planning, but that’s not easy with EV pricing, capabilities, and support infrastructure in flux. Determining the best vehicle models, their roles, and how many to purchase is more than tricky - it's a gamble.

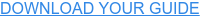

The most sensible approach is to proceed thoughtfully, transitioning from ICE (Internal Combustion Engine) vehicles without sacrificing agility and options. A fleet in transition is a mixed fleet, so the question at any point is:

What combination of vehicles will accomplish the goal?

There is an optimal ratio of EVs to ICE vehicles, the ideal EV ratio, which will maximize fleet profitability and sustainability. It’s unique to every fleet and quickly reveals the optimal EV models, their most effective utilization, the number of vehicles needed, and the most beneficial time to introduce them.

Calculating the ideal EV ratio requires software capable of analyzing transportation use cases specific to each company, and these must consider a multitude of factors:

-

Logistics use case scenarios and optimization potential.

-

Corporate goals, objectives, and business requirements.

-

Economic, financial, political, and technological constraints.

-

Enterprise system functionality and agility.

-

Government regulations.

-

Fleet size and operating theater.

-

Vehicle performance characteristics and costs.

These factors are subject to change, and the ideal EV ratio will follow. For example, EV utilization will expand as charging infrastructure, battery technology, and cost of ownership improve. On the other hand, uncertainties of transitioning to a net zero economy and bifurcation of the global economy may toss a wrench or two into current plans.

Robert Recknagel, Vice President of Manufacturing & Logistics at flexis AG, notes, “It's important for a business to understand the state of the technology to come up with the best strategic and tactical decisions. A business can buy equipment accordingly, and our system will do the operational planning based on the customer’s strategic planning. The tours will change to compensate for new vehicle constraints.”

Mixed Fleets Need to Know the Ideal EV Ratio

Knowing the ideal EV ratio is essential to optimize a fleet for maximum profit and sustainability. It also protects a company from making these common mistakes:

-

Adding Too Few or too Many EVs. Too few and a fleet realizes only marginal improvement with the added complexity of managing a mixed fleet. Too many EVs increase operating costs and constraints, with the bonus of decreasing performance, capacity, and agility.

-

Electrifying the Entire Fleet is often cost-prohibitive and a logistical impossibility. For most companies, a mixed fleet is optimal.

-

No Change. Keeping the status quo to avoid complications of a mixed fleet can introduce new risks. These include less profitability when oil prices are high, regulatory fines, forfeiting government subsidies, and lost revenue from customers who value sustainable practices.

Top Questions About Managing Mixed Fleets

Recknegal says transportation operators are looking for solutions to help them plan and prepare for the introduction of EVs and ongoing management of a mixed fleet. Some of the most common questions he encounters include:

-

What changes to our transportation network will make it more sustainable?

-

What are the latest regulations, and how can we prepare for them?

-

How can we handle future carbon tax issues?

-

How can I achieve and measure reductions in our carbon footprint?

-

How can I operationalize the data?

-

What can I contribute to our corporate target?

Fleet Simulations Provide the Answers

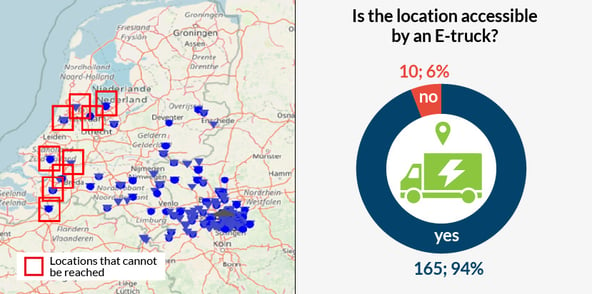

The questions may be the same, but the answers are unique for every company, and running a fleet simulation will provide them. flexis uses its Transportation Planning and Scheduling cloud flexis to do that.

The flexis solution integrates robust planning and execution capabilities to calculate the most effective utilization of each vehicle. The end product is the ideal EV ratio with supporting details, and the results can be surprising.

Recknagel notes, “We test whether or not a plan makes sense, like what would happen if a company converts 100% of its fleet to EVs, which is often prohibitively expensive, and some tours are not even doable because of the limited range of the electric trucks. If a new truck model comes out with an extended range and it’s more economical, that can change the whole strategy. The same is true if a company’s distribution pattern or variable costs change.“

Public Policy Can Make or Break EV Affordability

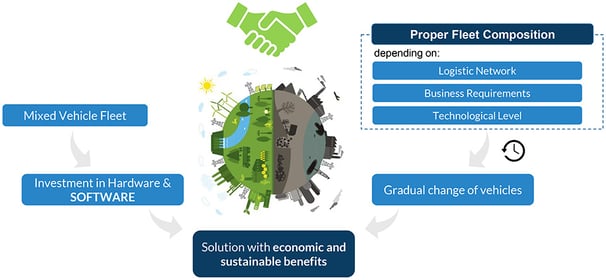

Regulations and incentives for alternative energy vehicles can significantly alter analysis results, so including them for each country with fleet operations is essential. For example, Germany provides tax reductions and toll waivers for electric trucks to offset the disadvantages of EVs, so sites located in Germany will favor a higher ratio of EVs.

Another decisive factor is public works projects that expand charging infrastructure along routes used. A thorough fleet analysis considers these projects and excludes EVs from areas that lack adequate charging support.

The Bottom Line Results

All this analysis comes down to the results a fleet can expect from adjusting its vehicle mix to match the optimal EV ratio. Consider the results an automotive supplier realized after running the fleet simulation with flexis.

The company relied on a fleet of heavy-duty diesel trucks for its inbound supply chain, and it wanted to reduce CO2 emissions. Their original assumption was that a major investment in a new electric fleet would be required, but running a fleet simulation with flexis revealed a surprisingly different answer.

The company relied on a fleet of heavy-duty diesel trucks for its inbound supply chain, and it wanted to reduce CO2 emissions. Their original assumption was that a significant investment in a new electric fleet would be required, but running a fleet simulation with flexis revealed a surprisingly different answer.

Running various use case scenarios and taking current regulations in Germany into account showed:

-

The ideal EV ratio of 15-20% would yield transportation savings of 1% while reducing carbon emissions by 35%.

-

Using software to optimize route and tour planning and execution could boost cost savings to the double digits.

Conclusion

Environmentally conscious transport does not necessarily have to be at the expense of the economic bottom line. The ideal EV ratio provides the answers, and running fleet simulations will ensure a fleet’s vehicle mix remain optimized as changes occur.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

Want to learn more about Multimodal Transportation?

Download our presentation and learn:

-

How can transports be planned quickly and yet flexible so that CO2 savings are verifiable?

-

How do you make optimal use of a multimodal transport network that maintains supply in both the short and long term?

-

How can you more easily realize a modal shift when disruptions occur? And how do you keep a grip on your CO2 emissions in doing so?

flexis and BigMile present a Use Case of a modal shift and show that network optimizations and sustainability often go hand in hand.

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers