4 Areas Where Production Benefits From Integrated S&OP

Robin Hornung - June 30, 2022

Production Potentials in an integrated S&OP process

In recent years, volatility in global supply chains and consumer buying behaviour have made sales and production planning (S&OP) more critical than ever. Traditionally, a production plan allows companies to map out how much of a product they need to make and how much raw material it will require. But the production plan is actually not that simple. It must consider constraints at all levels, even down to individual machines in the production line, in order to succeed. Plus, the plan needs to integrate supplier capabilities and last but not least with the sales forecasts, making it challenging to develop a resilient production plan without cross-talk across an entire company and even across the whole production network. S&OP solutions now make the process easier, with real-time data analytics that directly integrate with sales forecasting and materials ordering.

4 Ways an S&OP Solution Supports Production Planning

1. Maximize Your Production Capacity

With an S&OP solution, you can track what is requested by sales compared to what is ultimately produced or planned in manufacturing. To maximize this production efficiency, the solution can use capacity models that consider parameters such as manufacturing equipment outputs and working time that define a capacity limit. These models can even integrate advanced features such as production losses due to routine maintenance, changes in work schedules, and more. To maximize the efficiency of production resources capacity, the software then automatically identifies opportunities where capacity is not being fully utilized and alerts companies to instances where capacity is being exceeded.

2. Meet Sales and Production Goals

Usually, the production planning process begins once the sales team provides their forecasts and their unconstrained supply requests. The production plan then needs to facilitate the unconstrained sales plan, taking into consideration the entire timeframe and all necessary parts and equipment. With an S&OP solution, you can track what is requested versus what is ultimately produced to ensure the production plan aligns with the sales goals and production capacity. In case the fulfillment of sales requests requires stronger adjustments of capacities, which typically involve investments, a clear business decision is supported with an S&OP system, balancing cost on the production side with revenues on the sales side in different scenarios.

3. Improve Stability and Reliability of Production

The last few years have demonstrated the inherent instability of the global supply chain. Now, more than ever, companies need to develop a robust S&OP solution to support supply chain resiliency. When creating a production plan, a company needs to consider more than just one-month intervals. Instead, companies should consider at least the month before and after a target month to improve stability. An S&OP solution can generate a stable production plan over three months to support sales goals while maximizing capacity. Additionally, the S&OP solution allows quick replanning in case of unplanned shortages. It identifies affected production orders and exchanges them for unaffected ones. This at first glance creates a certain turbulence, but volume losses are avoided, and the changes are verified against all existing capacities. The impact of short-term events to the plants’ productivity and the overall profitability is therefore limited.

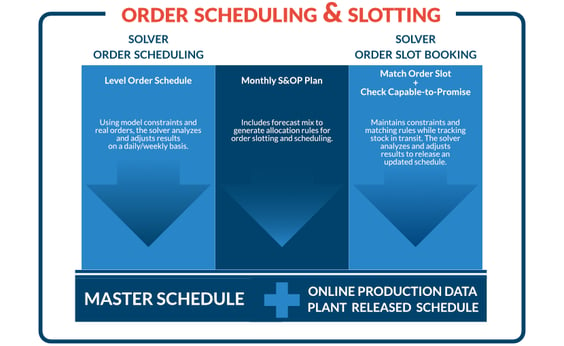

4. Easily Connect with Slotting & Sequencing Solutions

An S&OP solution take the high-level production plan and integrate it with monthly, weekly, or even daily scheduling solutions to adhere to granular constraints. To make sure your production plan is successful, it’s crucial for scheduling and slotting constraints to be extrapolated into the S&OP solution (i.e., only every one in three products can be green). This also facilitates faster replanning and reduces loss of product and profit when issues arise. One key element of an integrated flexis Solution is the Rückrechnung (Reverse Calculation) of constraints from granular levels such as part capacities by week to higher level primary product capacities by month, which are used in S&OP. A company can then ensure that all high-level S&OP plans will facilitate solutions for detailed production schedules, which are often done on monthly levels.

flexis Provides End-to-End Solutions for Production Planning

flexis Demand Capacity Management easily integrates with the S&OP software for fine-tuning on a daily level. With the daily bill of material, the production demand can be translated to parts demand to coordinate ordering and shipping to help maximize capacity. The flexis team can help you evaluate “what if” scenarios to work flexibility and resiliency into your production planning. Overall, the flexis suite of solutions can support faster replanning and more robust forecasting to ensure a successful S&OP.

More information

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach