Risk Free Digital Solutions for Supply Chains in 3 Steps

Keith LaBotz - April 13, 2023

The best answer for most supply chain challenges is digital solutions, but they come with risks that can present new challenges if left unchecked. Fortunately, your company can prevent that by following a few simple steps, and it will also lay a solid foundation for supply chain optimization.

According to PricewaterhouseCooper’s (PWC) 26th annual "Global CEO Survey," economic and geopolitical turbulence are the top risks for supply chains. Companies mitigate these risks with digital solutions, automating business processes with cloud apps, AI, and other technologies.

As organizations devote full attention to battling a three-year-old supply chain wildfire, digital solutions are often implemented with some urgency, leaving little time for analysis. Consequently, the risk of introducing data silos increases, and potential future problems will have to wait until the fire subsides.

Why Data Silos Present a Growing Risk for Digitalization

The wildfire has stayed the same since 2020, and every indication suggests it will continue indefinitely with the shift to a multipolar world. Economic and geopolitical turmoil will manifest as supply chain volatility and systemic risk will exacerbate it.

- Urgent implementation typically aims for immediate resolution, overlooking the impact on optimization and strategic objectives, which are crucial to long-term viability.

- The quicker a solution is implemented, the better. Cloud solutions make it easier, encouraging the proliferation of data silos.

Why Your Company Needs to Address Data Silos Now

Supply chains should address this potential problem now because the effects of data silos are cumulative. The consequences grow more severe over time:

- Despite the laissez-faire buzz about cloud solutions, they can be more challenging to remove due once integrated with enterprise systems - especially for solutions engaging supply chain partners.

- A patchwork of digital point solutions inhibits process improvements, reducing operational agility and efficiency.

- Disparate solutions need a cohesive framework for supply chain optimization.

- Without a common framework, process improvements concentrate on individual point solutions, reducing the benefits while adding systems complexity.

- As system complexity grows, the cost of maintaining and improving the process increase.

- As integration between systems increases, the potential for process improvements, agility, sustainability, profitability, and optimization decrease - a fatal trajectory.

The sooner a company takes action, the less exposure there is to these risks. With the following three steps, your company can address this issue now with relatively little effort.

1. Focus on The Last Mile

The first step is to focus supply chain digitalization efforts on the last mile, to keep digital solutions aligned with a supply chain's primary mission: to fulfill customer expectations at maximum profit. Given this common end goal:

- Last-mile logistics ensures digital solutions are selected and implemented consistently.

- Systems integration occurs around shared objectives, systems, and data collection.

2. RealTime Supply Chain Visibility

Few issues are as crucial for a digital supply chain as end-to-end visibility. While control towers and dashboards may be all the rage, the objective isn’t observing the supply chain in action; it’s about allowing systems to “see” data and optimizing.

Supply chain visibility should strive for invisibility, automating decision-making and collaboration across supply chain systems. Automated decisions depend on knowing when and where materials are in a supply chain, and that’s where a visibility platform like project44 helps capture shipment status from multiple logistics providers.

Once shipment tracking details are known, a shipment’s status links cartons and order line item SKUs. With transportation and order details cross-referenced, the location and ETA of goods in transit are known, enabling more effective short and medium-term planning.

3. Establish a Framework for Optimization

Implementing best-in-class solutions for each supply chain function allows a company to utilize the most capable vertical solutions and vendors. However, a common framework for optimization is essential for ensuring a cohesive process without data silos.

A supply chain optimization framework functions like a template for integrating individual solutions. Optimization depends on a holistic process, and a framework organizes each app and function around a data model, ensuring a cohesive approach.

Adopting this framework is never too late; it will help identify existing silos and prevent new ones.

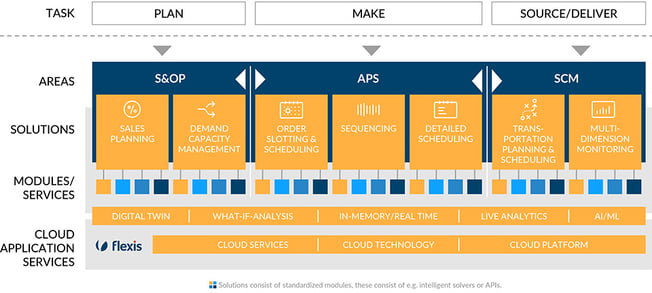

The flexis cloud is an example of an optimization framework that integrates transportation, S&OP, APS, and SCM (logistics) planning. These solutions continuously adjust planning across supply chain processes from sourcing thru production and final distribution.

In addition to preventing silos from developing, the flexis solution ensures digital solutions are deployed with the entire supply chain in mind with these capabilities:

- Global visibility and monitoring of orders and shipments and their effect on each functional area and their incumbent digital solutions.

- Iterative optimization between production, fulfillment, and transportation capacity.

- Detection of disruptions like changes in demand, productivity, resources, port bottlenecks, and transportation capacity.

- Continuous optimization of long-range forecasting (6 + months), mid-range tactical planning (3-6 months), and daily operational plans (from minutes in advance out to 12 weeks of execution).

Conclusion

Digital solutions are the best response to most supply chain challenges, but your company must also mitigate the risk of data silos. Following the three steps in this article will do that, and flexis AG offers the software and services needed to make it happen.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach