Lower Transport Costs With High Fuel Prices

Keith LaBotz - May 12, 2022

Controlling transportation costs in an inflationary environment is challenging, but it also presents an opportunity for long-term competitive advantages.

With so many issues to contend with right now; so why make transportation costs a priority? The cost of resources determines your company’s profitability and price competitiveness, and similar to a carbon footprint, there’s a footprint for shipping expenses. These accumulate across supply chains, and your company pays more for resources when they are not reduced.

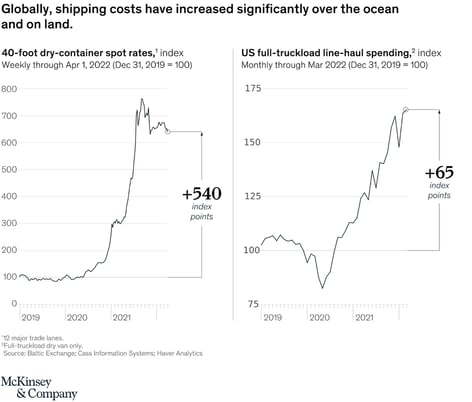

If that idea doesn’t grab your attention, maybe the graph below will.

The unprecedented escalation in transportation costs shown above is reason enough to move the transportation center stage. Decades of low-cost, plentiful transportation were severely disrupted by lockdowns, rising in the fall of 2020 after China reopened its factories.

Prices skyrocketed in early 2021 as capacity problems, bottlenecks, driver shortages, and port congestion overwhelmed transport networks. All of this before inflation and spiking fuel prices began dominating headlines in early 2022.

The problem to solve is not higher fuel prices. All companies arise and fall with the tide of oil prices, and like political policies, there is nothing your company can do to change it. However, there are many actions a business can take to reduce transportation costs.

Transportation cost is an aggregate of many expenditures: equipment, labor, systems infrastructure, financing, operating expenses, and fuel. Every company has different cost structures and can have the power to improve them significantly.

The good news is that transportation is an inefficient, wasteful process full of cost reduction opportunities. Improving the efficiency of the transportation process reduces fuel consumption and introduces numerous competitive advantages.

Instead of fixating on the price per liter of petrol, companies should consider how much work can be performed per liter; focusing on operational outcomes fuel. Here are five areas to consider for quick efficiency gains regardless of where fuel prices are headed.

1. Increase Equipment Efficiency

-

Tractor Aerodynamics: According to the North American Council for Freight Efficiency, streamlining tractors and trailers to reduce air drag is a relatively inexpensive and easy way to improve fuel efficiency and reduce carbon emissions, Cab and roof extenders, tractor-trailer gap devices, and streamlining mirrors, headlamps, bumpers, chassis, and wheel fairings can reduce fuel consumption by up to 15%

-

Idle Reduction Long haul trucks idle to power the driver compartment for heating, cooling, and electronics. The average truck idles for 1,000 hours a year which is costly, noisy, and adds to pollution. Idle-reduction solutions such as onboard diesel and battery units, engine start-stop, diesel heaters, and driver incentives drastically reduce engine idling.

-

Fuel Savings Programs: Many companies with transportation operations use fuel cards that reduce diesel costs by up to 5% and sign long-term agreements with fuel providers to stabilize fluctuating fuel prices.

-

Tire Pressure: Fuel consumption increases roughly 1.0% when a tire is underinflated by ten psi. According to the North American Council for Freight Efficiency, 20% of trucks operate with one or more tires underinflated by at least 20 psi. Automatic tire inflation systems eliminate this problem by keeping tires properly inflated. Benefits include 1-2% improvements in fuel efficiency, lower carbon emissions, longer tire life, fewer roadside breakdowns due to tire failures, avoiding fines for improper inflation, and increased driver safety. Payback typically spans around one year for many vendors, making this a relatively quick ROI.

-

Telematics: Telematics technology monitors driver behavior and truck performance, identifying opportunities to reduce fuel consumption. Examples of good driving habits include lower average speed, reduced idling, slower acceleration, slower braking, and shifting properly.

-

Routine maintenance: This one is so obvious, which may explain why it’s so often overlooked. Truck maintenance ensures equipment runs at peak efficiency.

2. Improve Sourcing

Sourcing strategies can significantly reduce shipping distance and transit times, strategic risks, and carbon emissions. This is likely to continue for years as the EU and US rethink China-based supply chain models conceived nearly forty years ago. New technologies and ways of thinking have evolved since, presenting fresh opportunities.

-

On-Shoring: Sourcing goods and materials domestically,

-

Near-Shoring: Similar to on-shoring, it involves sourcing from international suppliers on the same continent or offshore. For example, US factories would switch from suppliers in Asia to Mexico or Canada.

-

Dual Sourcing: Diversifying among multiple suppliers to reduce the risk of a single source. Redirecting to alternative suppliers would’ve significantly minimized and probably prevented the effects on US and EU supply chains from China’s 2020 lockdowns.

3. Diversify Distribution Network

Diversifying from a single distribution site into multiple regional warehouse locations can significantly reduce the distance, transit times, fuel consumption, and carbon emissions. This is the outbound equivalent of resourcing suppliers. It also provides resiliency, providing a backup fulfillment source if there are operational problems like inclement weather that prevent shipping from the usual location.

4. Consolidate Shipments

Solutions like flexis Transportation and Planning automatically assess future demand and distribution location to identify shipment consolidation opportunities. Grouping multiple orders within a warehouse and across a distribution network into a single delivery dramatically cuts transportation costs. The flexis solution can be cloud-based and implemented in just weeks, finding new savings.

5. Optimize Vehicle Routing

A routing optimization process like flexis ProfiTOUR can guide each vehicle to its destination at the lowest cost and ensure customer expectations are met. ProfiTOUR adjusts the delivery plan enroute with changing traffic and weather conditions to minimize labor and fuel consumption.

- On-time pickup and delivery.

- Reduces greenhouse gas emissions.

- Minimizes total delivery cost by economizing fuel consumption and driver time.

- Maximizes driver productivity by reducing wait times and avoiding traffic congestion.

- Compliance with driver time regulations to avoid costly fines for driver and company.

Conclusion

There are multiple ways to reduce transportation costs regardless of what happens with fuel prices. The suggested solutions can be implemented quickly and continue providing benefits long after fuel prices come back to earth.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach