Logistics Optimization: The Key To Better Supply Chain Site Selection

Keith LaBotz - March 30, 2023

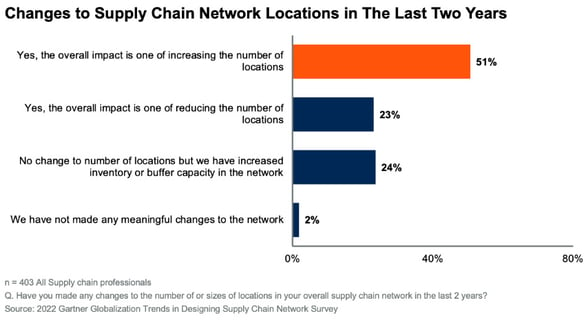

Onshoring, nearshoring, friendshoring. No matter what you call it, don’t change your supply chain network without first considering logistics network optimization.

The trend of relocating sites and adding new sites to supply chains can reduce costs, vulnerability to geopolitical and economic disruptions, and carbon emissions. It also alters a company’s logistics network, and a move could end up trading one set of risks for another.

Every site in the supply chain network is part of a local transportation ecosystem with a unique mix of constraints, infrastructure, transport modes, reliability and cost factors, and competition for capacity. Operational changes can be significant to accommodate these variables without compromising logistics performance. The differences can be substantial, especially when relocating production from Asia, where nine of the world’s ten largest ports offer abundant, inexpensive transportation.

No matter the relocation reasons, a company must discover the impact of transportation changes on its logistics network before selecting a new site. The presence of similar companies doesn’t imply logistics viability in a new location because every supply chain is unique. The only way to know whether a potential site is a good move for your company is to analyze your company’s data and use case scenarios with its logistics providers and suppliers.

Site Selection is About Logistics Optimization

Assessing the impact of relocation on supply chain logistics amounts to exploring the degree of logistics optimization possible given a site’s transportation ecosystem. Logistics network optimization software can quickly run simulations for many potential sites and conditions to reveal the answers a company needs when examining locations:

- Which modes of transportation can support logistics requirements and operational changes required to utilize them.

- How site-specific constraints impact production and distribution schedules and costs.

- Differences in shipping costs, risks, delivery performance, and their impact on lead times between multiple sites.

- The most favorable locations for production and distribution to support historical demand, forecasted growth, and the introduction of new products.

Logistics Optimization Goes Beyond Site Selection

The value of logistics optimization software is not limited to initial site selection - it is also enormously valuable for ongoing planning and daily execution.

The best logistics optimization software will work for site selection and optimizing transportation, production, and distribution in daily operations. Parameters used in simulations for site selection should transfer into the production environment to ensure expected results after relocation and to realize these benefits:

- Minimizing transportation costs and emissions.

- Reducing carbon emissions, labor costs, and fuel usage.

- Eliminating waste and fully utilizing transport capacity.

- Improving contractual arrangements with logistics providers.

- Increasing operational agility.

How To Increase Logistics Optimization

Because transportation is the core of a supply chain, the potential for logistics optimization depends on the functionality of the Transportation Management Software (TMS). Most TMS apps concentrate on narrower, short-term shipment planning (a few days out) and execution, with a strong bias toward outbound fulfillment.

Expanding TMS capabilities can improve the visibility and control of shipping processes, enabling further integration with upstream procurement, production, and fulfillment planning (logistics). The degree of logistics optimization possible depends on the extent of integration between these supply chain activities.

flexis Cloud for Logistics Optimization

flexis AG provides a solution for manufacturers that offers the functionality discussed; it automates initial site selection and ongoing logistics optimization in a supply chain network.

The flexis cloud provides APIs for running use case scenarios to determine optimal transportation planning & scheduling across a supply chain. Site locations can be changed and evaluated individually in light of operational objectives, such as sustainability goals. These and then evaluated at three levels to determine changes to maximize objectives:

- Strategic: Identifying optimal locations for sites in a network relative to business requirements.

- Tactical: Monitoring and optimizing logistics activity across sites in the network.

- Dynamic: Optimizing resource utilization at each site, e.g., transportation, production, and order planning.

The flexis solution implements rapidly and includes TMS functionality so companies can expand optimization potential across all three levels noted above. Functionality critical to achieving logistics optimization include:

- Continuous Planning: Long-range forecasting (6 + months), mid-range tactical planning (3-6 months), and daily operational plans (from minutes in advance out to 12 weeks of execution) integrate into a single, cohesive view.

- Transportation Planning and Scheduling: Adjust shipping plans across the logistics network with changing demand, productivity, resources, transportation capacity, and unexpected disruptions.

- Order Slotting and Scheduling: Continuously adjust production and transportation planning and execution as transportation, and production constraints change.

- Inbound Freight Optimization: Adjusts supplier shipping and factory production schedules with changes in demand and delivery schedules.

- Consolidation Combines orders into single shipments and multiple shipments into multi-stop truckloads in coordination with production and distribution schedules.

- Shipping Automation: Procurement and tendering of shipments coordinated around production scheduling, fulfillment schedules, and available yard and dock space.

- Optimal Carrier Selection: Least cost and lowest carbon delivery mode selection minimize shipping costs and emissions.

- Loading Optimization: efficient, full utilization of space and most efficient unloading sequences when using ocean, multi-modal containers, and trailers.

- Vehicle Routing Optimization (VRS): Automates and optimizes fleet operations.

- Multimodal Optimization: Expands transportation capacity and minimizes costs by enabling combinations of multiple transport modes like truck, rail, ocean, barges, and air freight.

Conclusion

Changes to supply chain network locations can introduce significant benefits when logistics optimization occurs and serious problems when a logistics network is compromised. Using software to optimize logistics across the supply chain network is the key to identifying optimal site locations and maintaining peak logistics performance as constraints change.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

Want to learn more about Multimodal Transportation?

Download our presentation and learn:

-

How can transports be planned quickly and yet flexible so that CO2 savings are verifiable?

-

How do you make optimal use of a multimodal transport network that maintains supply in both the short and long term?

-

How can you more easily realize a modal shift when disruptions occur? And how do you keep a grip on your CO2 emissions in doing so?

flexis and BigMile present a Use Case of a modal shift and show that network optimizations and sustainability often go hand in hand.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach