It’s Time for More Visibility in the Manufacturing Supply Chain

Nancy Sarpolis - June 20, 2023

Today, it’s possible to track a package from the moment it’s ordered, follow your rideshare on a navigation app as it approaches your location and track lost luggage or pets using modern technologies. Some pizzerias even allow you to track the progress of your pie as it moves from prep table to oven to carryout box.

Real-time visibility has become so commonplace that it’s hard to imagine living—or working—without it. The agricultural industry, for example, has long embraced the idea of greater visibility into farming operations to safeguard public health by quickly identifying instances of contamination and tracing them to their source.

So why are manufacturers reluctant to jump on the visibility bandwagon within their own four walls?

Transparency is a top priority

Manufacturing sectors and services historically tend to adopt technology much slower in comparison to other sectors. Despite the potential of Industry 4.0 and the increasing interest from the manufacturing industry, the adoption of Industry 4.0 is still lagging behind in the manufacturing industry. And, in the aftermath of the pandemic, many manufacturers are trying to balance a more resilient supply chain against the constraints imposed by cash preservation.

U.S. manufacturers recognize the potential of Industry 4.0 to create value, but they have yet to fully appreciate the scope and magnitude of the opportunity or find the path to success, according to research by The Boston Consulting Group (BCG).

Yet increased visibility remains one of the top priorities among supply chain leaders. A recent report of more than 500 companies showed that 58% said increased end-to-end visibility in their supply chain was among their top two priorities.

The benefit of greater visibility

Manufacturers of global brands with complex supply chain challenges benefit most from the use of integrated solutions with an end-to-end view across their entire enterprise. “A holistic end-to-end view of the supply chain helps companies track materials and supplies, understand supplier working conditions and collect data to measure their program effectiveness,” according to EY. “Technology offerings can also identify and introduce efficiencies in operations and resources.”

Whether it is planning strategy, material procurement, order allocation, or warehouse and container management, real-time insight into the supply pipeline through intelligent solutions and software can form the basis for more efficiency and productivity for manufacturing operations. Imagine the benefit of seeing sales orders as they come in, monitoring the supply of parts in real-time, and comparing inventories, shipments, and production on a detailed dashboard that allows planners to drill down to the parts level to identify any potential problem areas before bottlenecks occur.

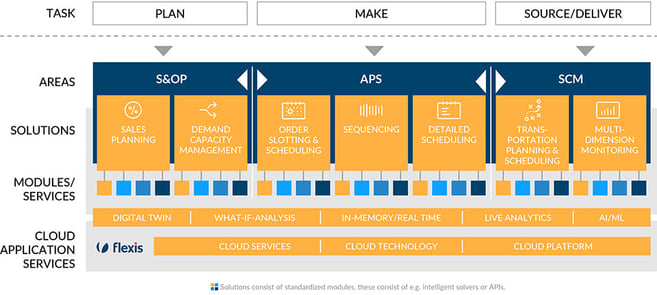

Industry 4.0 technologies such as Advanced Planning and Scheduling (APS) solutions, for example, can track supply chain activity as it’s happening across the factory floor. Interconnected modules can look at the relationship between sales and production (Order Slotting & Scheduling), plant capabilities (Detailed or Job Shop Scheduling), and the optimal schedule to maximize production efficiency (Sequencing).

flexis portfolio of composable cloud solutions

Advanced planning and scheduling (APS) solutions can help companies gain a comprehensive overview of the entire value chain and ensure that all departments within the supply chain have the latest information and can operate accordingly. For example, APS solutions can alert the production team to new orders as they come in through the sales team. In a smart manufacturing process, the software system then mediates real-time data between sales and production. Through planning and sequencing, manufacturers will know how many materials they need, which equipment should be used, and the most optimal times to produce specific products.

Better decision-making and improved workflows

The importance of real-time visibility in today’s globally connected supply chain cannot be understated.

“A fully transparent supply chain allows everyone involved to make better decisions and improve their workflows,” says CEO Today.

And, once you open the window into greater supply chain visibility through Industry 4.0 technologies, you’ll wonder how you ever got along without them.

If you want to learn more get your Guide to Cloud Manufacturing

In this Guide you will learn:

-

New potential of cloud-based manufacturing

-

Opportunities of the cloud for the production

-

Technological advantage of flexis technologies

Or do you want to learn more about the Gartner Top Trends in Strategic Supply Chain Technology 2023?

Get your download here:

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach