Digital Supply Chains: How to Avoid the Hidden Risks

Keith LaBotz - December 01, 2022

Your company’s new digital solutions may add value to your supply chain process, plus something else - hidden risks.

Two years of battling a supply chain wildfire and a dim economic outlook have put enormous pressure on businesses to transition to a digital business model.

All eyes are on the promise of a digital supply chain: increased profits, agility, sustainability, and customer satisfaction. Growing economic uncertainty adds urgency; unfortunately, many companies are charging into the digital abyss without considering the risks.

So let’s pause to consider the hidden risks of digitizing the supply chain:

- Can you list the risks your company expects to encounter with its new digital supply chain process?

- What solutions has your company put into place to mitigate them?

If you came up with a list of risks, your thinking is ahead of most. Your company is ahead of the curve if it has solutions to resolve them. Even if a business addresses both, it may still be at risk. The risks that are missing from your list should concern you the most.

McKinsey, BCG, KPMG, and Bain & Company report that 70% to 95% of digital transformation projects fail. Digitization can add more risk to your supply chain as readily as it can add more value, creating a significant problem.

The good news is that your company can adopt a few quick remedies without losing its pace to eliminate supply chain digitization risks.

Digital Supply Chains Require a Radically Different Perspective

Transition risks are inherent when migrating to a new paradigm. A digital supply chain is radically better because it’s a fundamentally different process than the legacy process your company is leaving behind.

A radically different process requires a different perspective, which usually necessitates a different approach. You can’t build a digital supply chain with a legacy mindset. Your company will need new supply chain strategies, tactics, and tools to realize the full potential of a digital process.

Building a digital supply chain requires examining your company’s enterprise from the outside. That’s the opposite orientation from the legacy supply built around ERP systems which fixated on everything with the enterprise's four walls.

We naturally perceive the world through the familiar lens of the past, so it's important to ditch the old mindset.

- Take an end-to-end view of process improvements, seeing the software process as a function in a supply chain network instead of your company’s enterprise system.

- Assume a holistic view that considers the impact on external supply chain partners.

- Adopting the perspective of external supply chain partners will reveal risks affecting their operations.

A Resilient Approach to Process Improvements

Resilience is the biggest buzzword around right now. When things change, individuals, organizations, and supply chains must be agile to bounce back from unexpected disruptions.

The steep learning curve of venturing into the brave new world of digital supply chains is the source of most of those hidden risks that did not appear on your list. Your company will first learn what they are when encountering them, and then it will need to mitigate them on the spot.

How can your company mitigate risks when it doesn’t even know what they are? That’s where resiliency comes in.

Your company will not only need a resilient business process, but it will also need a resilient approach to making process improvements. Promoting software changes into production requires a resilient process with these capabilities:

- End to End Visibility: to detect real-time exceptions across the supply chain.

- Transparency: to trace an exception back to the source where risk can be identified and mitigated.

- Actionable Data: to respond to exceptions to minimize the impact.

- Roll-Back: Contingencies to roll back to a less risky state.

Prioritize Transportation Logistics Improvements

Over the past two years, much of the digitization effort concentrated on increasing supply chain agility to combat unprecedented volatility. Businesses should continue to pursue this objective with a tiny change: focus digitalization improvements on transportation logistics. Why?

Transportation is the core of every supply chain; every supply chain function ultimately links to a shipment, and this has far-reaching implications:

-

Transportation is the easiest and most effective point for detecting and correcting errors in a supply chain. Shipments link all enterprise and external supply chain processes. Data and process errors show up in shipping, where they can be easily traced to their source and corrected.

-

A healthy transportation process results when all upstream processes are healthy. Focusing on improving transportation health drives process improvements in the supporting functions enterprise-wide, improving overall supply chain performance.

Integrate Transportation, S&OP, APS, SCM

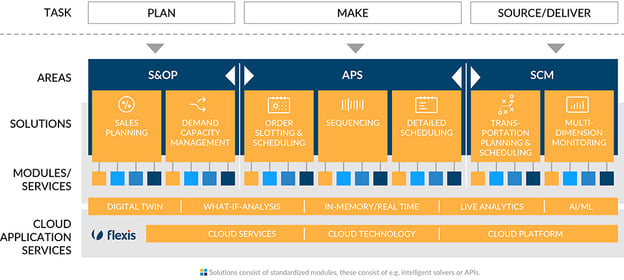

Supply chain optimization is the ultimate expression of supply chain health. The most effective way to do this in a digital supply chain is by integrating transportation, S&OP, APS, and SCM (logistics) planning and execution. The flexis suite of apps is a cloud-based solution that makes integration straightforward.

Conclusion

Your company can eliminate hidden risks by adopting a holistic perspective of its supply chain and concentrating on improving transportation. flexis AG offers the technology and services for implementing the solutions discussed in this article.

INTERESTED IN MORE INFORMATION?

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach