A Winning Supply Chain Strategy for Booms and Busts

Keith LaBotz - July 21, 2022

Organizations usually cut discretionary expenditures and begin downsizing operations when an economic downturn appears imminent. Not anymore.

Downsizing comes with risks, and a new cost reduction strategy can avoid them, putting competitors at a considerable disadvantage. Traditional cost-cutting might become as hazardous as an economic recession.

This new strategy employs cost optimization instead of traditional cost-cutting, and it’s superior in every respect. Unlike corporate austerity measures, cost optimization works equally well in economic booms and busts. The only problem is many companies don't realize this powerful tool is at their disposal.

It’s one of those unexpected discoveries. Supply chains are building more agile processes to neutralize supply chain volatility, not to invent an alternative to downsizing. However, that's what many are creating without realizing it.

As recession talk grows louder, the connection between agility and cost optimization appears. You’ll see it, too, after reading this article.

Cost Optimization is a Byproduct of Agility

The ultimate goal of an agile business process is supply chain optimization. Supply chains attempt to minimize cost and maximize value for stakeholders, and this outcome is much more difficult in volatile conditions. The same is true during market contractions, like a global recession.

An agile business process seeks to minimize cost; cost optimization is a byproduct. Supply chain planning and execution respond to changing conditions by steering enterprise processes towards lower-cost execution. An agile business enterprise is an alternative approach to traditional cost-cutting, and it has significant competitive advantages.

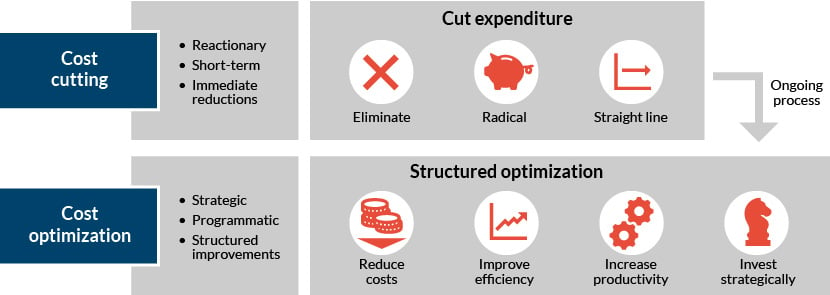

Cost Optimization is Radically Better

Source: Gartner

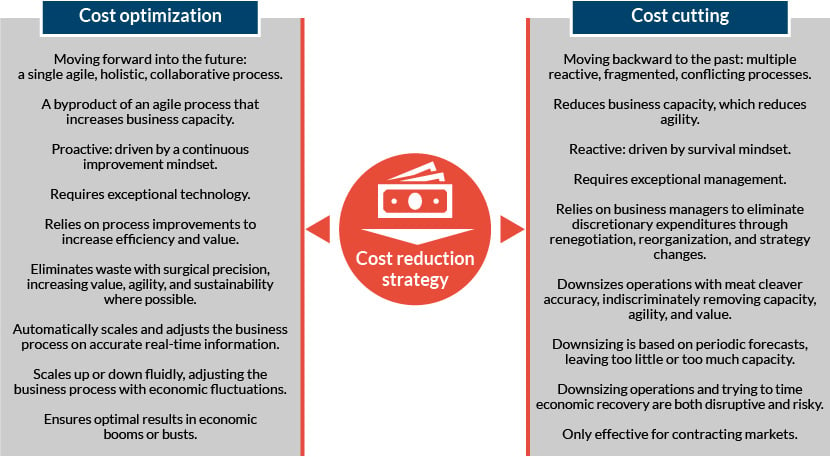

Both cost optimization and cost-cutting reduce expenses, but they are based on radically different perspectives, business strategies, and technologies. As you might suspect, this leads to radically different outcomes.

Source: Gartner

Cost Optimization is a Game Changer

An agility gap could develop in supply chains, favoring a minority of more agile companies.If this does materialize, the agility of a company’s business process will become a more significant determinant in how a business fares in changing market conditions.

Most organizations investing in digital technologies, perhaps 50-70% of companies, have not realized meaningful gains in agility to date. For these companies, cost optimization is not an option. Downsizing is their sole recourse in a recession, and all of the negatives previously noted are imbued on these businesses.

In the past, all companies downsized and had to compete with reduced capacity. There was no other alternative for surviving a downturn, but that’s no longer the case.

Cost optimization ensures full business capacity with a more variable business model. This begins with an adaptive business process that rightsizes capacity and eliminates waste with every shipment. Workflow and decision-making are highly automated and intelligent, instantly allowing the process to scale up or down as needed.

Cost Optimization Requires Holistic Thinking

Achieving the best possible outcome requires extensive analysis of scenarios and factors beyond immediate execution. Supply chains are networks involving complex interactions with multiple stakeholders and business systems. Optimization requires holistic thinking; it evaluates conditions across the business enterprise and supply chain.

For cost optimization to work, there must be alignment with internal business processes, corporate objectives, economic considerations, and relationships with external trading partners. Gartner identifies five areas to address when implementing cost optimization.

- Flexible vendor and supplier relationships must be established to support variability in the business process.

- Supply chain planning and execution must be tightly integrated to support decision-making based on: changing future demand and constraints, supply chain transportation, and requirements for order fulfillment and procurement.

- AI analytics must be capable of identifying and acting on cost-saving opportunities. AI and preprogrammed are needed to initiate action automatically.

- Workflow should be automated to the fullest extent, ideally with robotics.

Solutions like flexis Sales Planning, Demand Capacity Management, and Transportation Planning & Scheduling make it easier for companies to satisfy the above requirements and provide the analytics needed for cost optimization.

Conclusion

Cost optimization is a byproduct of an agile business process and offers a new cost reduction strategy that leads to radically better outcomes in economic booms and busts.

flexis AG provides software and services to help companies implement cost optimization.

You want more information ?

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach