5 Steps To Carbon Accounting In The Supply Chain

Keith LaBotz - March 09, 2023

Carbon emissions are the de facto currency of supply chain sustainability, yet measuring emissions is a roadblock for most companies. Your company can move forward with carbon measurement and accounting by following the five easy steps outlined in this article.

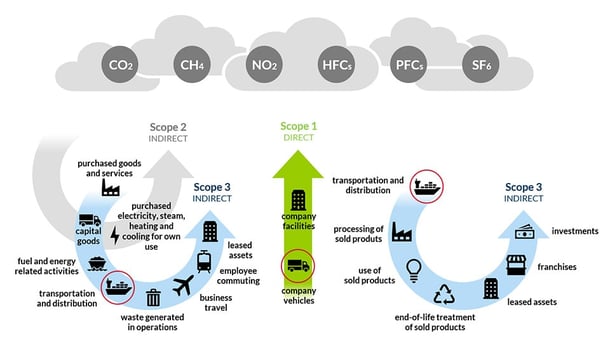

Boston Consulting Group (BCG) surveyed more than 1,600 organizations in 14 major industries in 18 countries to assess the overall state of carbon accounting in the supply chain. Each company had 1,000+ employees and revenues of $100 million to $10+ billion, and according to BCG, these companies account for more than 40% of global emissions.

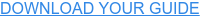

Source: epa.gov

Here are some findings from BCG’s survey that might interest you:

-

10% of organizations thoroughly measure Scope 1, Scope 2, and Scope 3 emissions.

-

81% partially measure emissions in at least one of the three scopes.

-

The average error rate of measurement ranged between 25% to 30%.

-

While 92% of all emissions are generated by Scope 3, only 12% of the companies surveyed make Scope 3 a priority.

Interpreting the Survey Results

The survey reveals little progress in carbon measurement, and BCG's conclusion urges companies to accelerate the effort. Searching for the devil in the details leads to this interpretation of the results:

-

An average error margin of 25% - 30% indicates most companies engage in educated guesswork. Imagine if financial accounting had this degree of inaccuracy - it doesn't work any better with emissions. This suggests a difficulty in capturing reliable data.

-

88% of companies focus on Scope 1 and 2 activities, but these only represent 8% of all emissions; most effort is inconsequential. This suggests Scope 3 is more difficult.

-

All companies need help measuring Scope 3 emissions, which are responsible for 92%. Success depends on collaboration with external partners, which will continue to be a problem until someone solves the Logistics 4.0 riddle.

-

While most companies checked the box “measuring emissions,” their responses are not quantified. Considering the other issues noted, skepticism about the efficacy of these measurements is warranted.

Caution: Carbon Accounting is Early Stage

The above findings are consistent with early-stage development, which may partially explain the reported slow progress. It also calls into question a related issue about the direction of carbon accounting and sustainability in general.

Sustainability is an attractive proposal with widespread support, but there is little agreement over how it will come to fruition. The assumption is that a new sustainable model awaits supply chains beyond the murky path ahead. That may or may not be true, but it assumes companies will develop carbon accounting capabilities that are accurate enough to manage carbon as a new currency:

-

Carbon and cash are the currency of the sustainable model.

-

For the sustainable business model to work, carbon accounting must have the same precision used in traditional finance.

Here are a few questions to consider before deciding how your company will proceed with introducing a process to measure CO2 across Scope 1 - 3:

-

How long will it take for carbon accounting precision to mature to support the sustainable business model?

-

How will measuring carbon emissions benefit your company today?

-

What process improvements can your company make now that will immediately improve sustainability, profitability, and agility?

BCG’s survey presents an underwhelming start for measuring CO2, but your company can progress with carbon accounting by following four steps.

1. Focus on Current Requirements and Remain Open to Change

Fortunately, supply chain sustainability can work without a sustainable business model. Instead, consumer choice, personal commitment to eco-friendly practices, and regulatory compliance can continue to drive sustainability.

The critical point is to remain open to changes and to focus carbon measurement and accounting efforts on current requirements without attempting to predict the future. Given its early stage, companies should begin carbon measurement with the expectation sustainability might take a new path.

Starting now will familiarize your company with carbon accounting in general and allow data collection, processing, and accuracy to improve. The sooner the learning curve begins, the further your company will advance with cost and carbon reductions.

2. Introduce Carbon Accounting Into Continuous Improvement

The most effective approach to carbon accounting is introducing it into existing continuous improvements one process at a time. Giving priority to improvements that reduce cost and efficiency and adding parameters to calculate emissions advances cost savings and carbon accounting.

3. Concentrate Carbon Accounting Efforts on Transportation

Transportation occupies a unique position within the supply chain, making it ideal for focusing efforts on reducing costs and emissions. The first illustration in this article hints at this, with transportation highlighted as the only activity appearing in all three emission Scopes.

Concentrating process improvements on transportation to expand carbon accounting is optimal for several reasons:

-

Transportation is the physical link connecting supply chain parties, providing an entry point to manage emissions in each Scope.

-

It is the core of every supply chain; a supply chain stops if shipments stop.

-

Transportation is central to the business enterprise business process, with every process supporting the receipt or shipment of goods.

-

Transportation accounts for 38% of carbon emissions in the US, presenting the most significant carbon footprint of all categories.

-

It is one of the most inefficient activities in the supply chain, offering abundant cost and carbon reduction opportunities.

-

Process improvements to transportation often have an extraordinary impact that extends to supply chain partners.

4. Use Shipments to Map Carbon Accounting

Transportation touches every aspect of a product’s lifecycle, from sourcing to returns and recycling, presenting an easy audit trail for cost and carbon.

- It can map the carbon footprint of every inbound and outbound delivery regarding sourcing raw materials to recycling and disposal.

- Each leg of a SKUs delivery through the supply chain provides a natural path for measuring the carbon footprint.

- Each enterprise process with its carbon footprint associated with the shipment can be mapped and carbon allocated to the SKU.

5. Operationalize Carbon Accounting

Approach measuring and managing carbon emissions and operating costs in the same manner - it must be operationalized. Embedding carbon metrics and management into enterprise software processes makes it transparent to the user and automates accounting. More importantly, it’s essential for supply chain optimization.

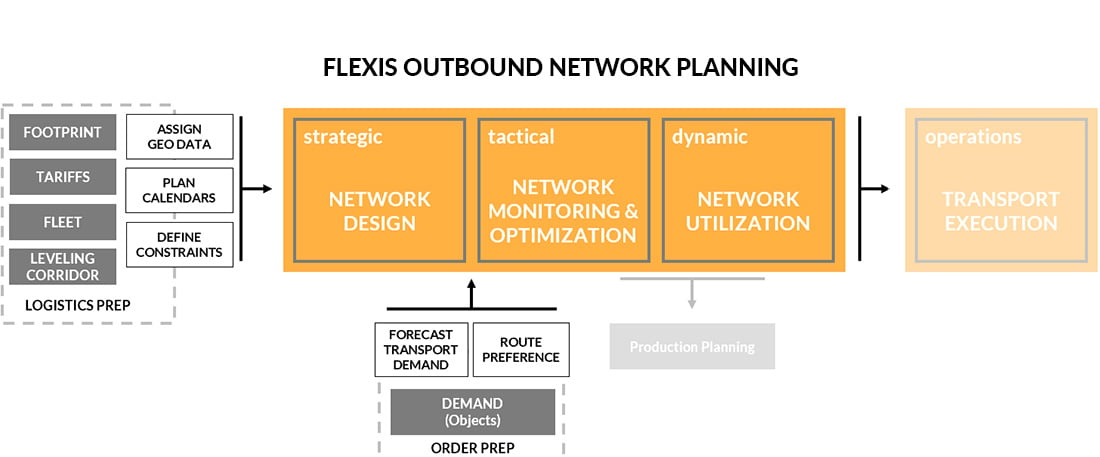

For example, flexis provides a cloud solution for transportation planning & scheduling that can build, maintain and optimize logistics networks in terms of

Strategic: Optimizing Network design, finding locations, relations or cost model

Tactical: Monitoring and optimizing the transportation network

Dynamic: Optimizing network utilization, e.g., transport order planning or capacity control

With a constant optimization process in planning you can improve your carbon emissions, supported by functionalities like:

-

Automated Vehicle Routing and Scheduling (VRS) that plans multi-stop tours around profitability and sustainability goals.

-

Shipment consolidation to reduce labor, fuel expenses, and emissions.

-

Transportation planning and scheduling which - integrated with S&OP data - plans resources for inbound and outbound shipments more proactively to avoid bottlenecks.

As a cloud-based service, the flexis solution can readily connect to a carbon analytics and reporting platform like BigMile for reporting and analysis of transport-related emissions.

Conclusion

Your company can keep carbon accounting progressing under all circumstances by following the five steps in this article. flexis AG works with companies to implement measurement and accounting for freight carbon emissions and can facilitate the steps presented.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

Want to learn more about Multimodal Transportation?

Download our presentation and learn:

-

How can transports be planned quickly and yet flexible so that CO2 savings are verifiable?

-

How do you make optimal use of a multimodal transport network that maintains supply in both the short and long term?

-

How can you more easily realize a modal shift when disruptions occur? And how do you keep a grip on your CO2 emissions in doing so?

flexis and BigMile present a Use Case of a modal shift and show that network optimizations and sustainability often go hand in hand.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach