5 Steps from zero to a collaborative S&OP Process

Robin Hornung - December 07, 2021

To plan stable and efficient business operations such as sales, production and transportation was never as challenging as in today's volatile world. Companies are challenged with growing product varieties and strong worldwide competition in times of high-cost pressure and logistical challenges around the world. Within all this uncertainty far out sales plans need to be established which form the basis of budget plans and established capacities in own production facilities and supply networks. Once the budgets and the framework is allocated the process moves into a cyclic re-planning process with measurement of goal achievement and adjustments of plans to be efficient, flexible and profitable. This is how an innovative S&OP process could look like.

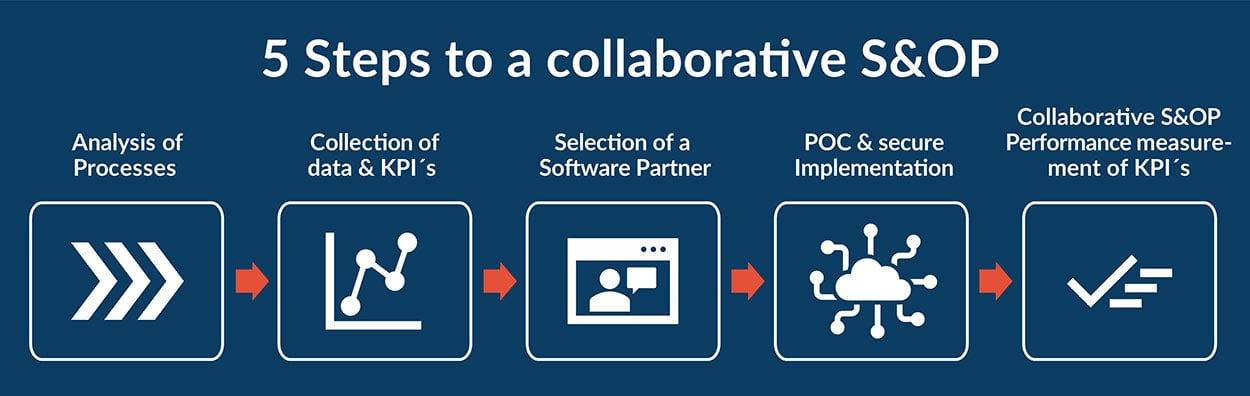

And the path to get there seems to be like a hike up the steepest mountain, which we are trying to break down into 5 doable steps. Sounds complicated and big? It bloody hell is – and the biggest challenge is right away on your side - but with a clear approach, all the advantages are on your side in the end:

Step 1 which is to bring stakeholders of all participating departments to the table and have them buy in to a collaborative process.

Everybody will need to give up something and everybody will need to provide something additional to the process for the sake of an overall improved process. Once this is achieved, we do not just need the general commitment but have to work on a new process with the referring goals. You may want to consider doing this with some external support to structure the overall process into steps in the different departments. Unless your product is a one-colour Gummy-Bear produced in one plant and sold in 5 markets you will find out immediately that the amount of information that is needed for an integrated plan across multiple company divisions is so huge and diverse, that this new process can only be brought to life if it is accompanied by supporting flexible information systems. Which brings us to

Step 2 which is to be clear of process requirements and information requirements which then can be mapped to high level system requirements.

You will answer some of the following questions

- What is the time horizon into the future, that should be covered with an integrated system?

- What is the planning rhythm and timely granularity, is it annual plans for budgeting with rolling monthly cycles of plan adjustments – all planning in monthly buckets of demand and capacity?

- What is the product level for planning in the different divisions? The tricky part here is, if everything is planned on lowest level of detail, then your planners will go nuts and will not adopt the new process. But if the level is not detailed enough, then we will get bad awakenings in the execution horizon.

- What is the main planning information to manage your process and what are the KPIs to permanently monitor efficiency, achievements and profitability?

- What is the scope of a solution in terms of sales-, production- and logistics networks? can we plan on higher levels in these structures, or do we have to plan down to the level of point of sales and assembly line?

- Monetary evaluations and the integration controlling and financials planning – in scope or not?

- What are the business rules between the participating parties in terms of timing, deliverables, responsibilities, and duties?

A lot of capabilities you do not have to ask for unless they are specifically important to you, because your software partners will tell you about them anyway. A lot is state of the art like planning in the cloud and in digital twins with syncing these twins to the central instance. Everybody has some AI and algorithms to support planning functions, which is fine, but in the end, you will have a planner making the decisions and human intelligence still is better than the trained algorithm. Also, systems nowadays are flexible in terms of their structures, functions, and planning parameters in order to support agile approaches not only in the software project but also in the daily operations which will later use the software. Once these questions are answered you are good to move on to

Step 3, the selection of software partner

Tough for us to stay neutral, since we are such a software partner, but okay… we will try and come up with a fair little list of rules, recommendations, questions, and hints:

- You have no clue what is out there? Do a market analysis, get a consultant to support you, check some of the known analysts for some guidance here and go to neutral tool-selection websites.

- Conduct a high-level study and get your list down to something like 5 companies that you invite to participate in a RFI, based on the requirements you have defined in Step 2.

- Have them present their standard tools and kick 2 out in order to quickly move on to check the commercial thoughts of the remaining 3 in a RFQ.

- By the way, we are in the 21st century, we all have configurable demo systems in clouds. Approach the software companies, if it is possible to set a test system up for you at low effort and low cost. Nothing is better than trying things out.

- Integration: you will be hammered with integration concerns and tasks and technologies and here is the golden advice: simply ignore all this crap for now. Yes, we will need to integrate solution, feed it, get information out. But honestly: all this is just doing and is neither a challenge nor a risk or cost driver for the overall project.

If you choose a S&OP Solution and software partner you should clearly express your expectations and objectives, discuss these honestly with your software partner and don’t force the software vendors to promise savings they can not provide in the end. So, with all your expertise select the software partner for this initiative and be aware of the fact, that the lifecycle of a typical S&OP solution is longer than the average marriage and often as challenging.

Step 4 the design, build, test and roll out of the system

Whether you prefer waterfall with quality gates or agile with rapid prototyping – there is no general recommendation. What’s important is to be on the same page and make sure expectations are the same and the rest depends on the type of business and the type of software that is selected. Make sure the requirements are clear and establish quality gates to measure the achievement of these requirements.

The other golden advice is, to include as many future users as possible already in design and test phase in order to lay the foundation of a good acceptance. There have been good systems in the past which were not extensively used because it was “not invented here” and “not built for our individual process”. But when the users are included early, a new process and a new system is most likely adopted in a more positive way and therefore can be brought to life at a higher success rate.

Step 5 Post Production adjustments

Give your organization time to adjust and allow a loop of process and system adjustments. In Step 2, the agile software was one of your main requirements – now you need this capability, because some things need to work differently than originally expected and therefore need to be adjusted.

And if everybody stayed calm, discussed honestly and keeps the focus on the common overall process, then you will be able to harvest the fruit of all the work required to get here, because a collaborative S&OP process which integrates all key players in one central planning process and planning system is your key to success.

- Your sales will go up, the cost for sales will go down.

- Efficiency of production areas will go up due to goal-oriented flexibility and buildable orders.

- Logistics cost will go down due to less unplanned freight and more stable production plans.

- Flexibility will be established where it is needed – but not more than needed.

- Overall profitability will go up.

- Speed in decision making, in adjustments, in reaction will be increased.

Want to learn more? Get your Guide for Sales & Operations Planning

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers