- All

- APS - Advanced Planning and Scheduling

- APS - Detailed Scheduling

- APS - Order Sequencing

- APS - Order Slotting

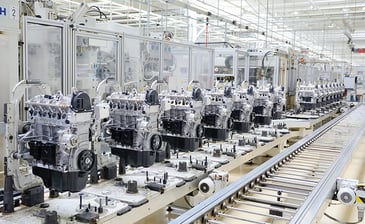

- Automotive

- Cloud Technology

- Digitization

- Gartner

- Industry 4.0

- Logistics

- Manufacturing

- Multimodal Transportation

- S&OE - Sales & Operations Execution

- S&OP - Demand Capacity Planning

- S&OP - Sales & Operations Planning

- SCM - Multi Dimension Monitoring

- SCM - Network Planning

- SCM - Supply Chain Management

- SCM - Transportation Planning & Scheduling

- SCM - Vehicle Routing & Scheduling

- Success Stories

- Supply Chain Planning

- Supply Chain Trends

- Sustainability