The IT Manager’s Guide to Supply Chain Logistics

Jesse Kelber - February 13, 2020

IT managers and logistics managers have more in common than you might think. Both require transparency and the real-time data it enables in order to be effective in their roles. Both also thrive in the decision-making process and all the back-and-forth with stakeholders that it entails. At the same time, there are of course glaring differences. IT teams work with end-user computer hardware, software, and networking technologies every day, while logistics planners interact with their own hardware with the sole intent of making goods move smoothly on their journey to the customer. Both are customer service oriented, it’s just that the IT manager’s customers are within the same company while the logistics manager’s customers are outside client companies. It’s that root level focus on customer satisfaction that drives both roles.

IT managers and logistics managers have more in common than you might think. Both require transparency and the real-time data it enables in order to be effective in their roles. Both also thrive in the decision-making process and all the back-and-forth with stakeholders that it entails. At the same time, there are of course glaring differences. IT teams work with end-user computer hardware, software, and networking technologies every day, while logistics planners interact with their own hardware with the sole intent of making goods move smoothly on their journey to the customer. Both are customer service oriented, it’s just that the IT manager’s customers are within the same company while the logistics manager’s customers are outside client companies. It’s that root level focus on customer satisfaction that drives both roles.

The Role of IT in Supply Chain Logistics: The 5 Things Logistics Needs From IT

Transparency and real-time dataflow are the two underlying crucial aspects of the relationship between IT and logistics that we’re going to focus on today. In order for logistics managers to be effective and keep their customers happy, they need to know as much as possible about the status of the end-to-end supply chain that they’re part of. And at the same time, they need the data generated by their teams and processes to be visible to every other relevant stakeholder across the value chain. This reliance on smoothly flowing data is why the primary functions logistics managers need from their IT department revolve around transparency. Below, we’ll give an overview of five critical pieces of this visibility puzzle that every logistics manager and planner need from their IT team.

Robust Network Infrastructure

No transparency project would get off the ground running on network infrastructure from the last century. End-to-end supply chain visibility requires cutting-edge network capabilities that reach all corners of both your organization and your supply chain partners. Real-time dataflows rely on high bandwidth and low latency. That means the fastest connection speeds combined with the lowest possible levels of interference from other systems. If a shipment takes longer to pick and pack than usual, or there’s unexpected downtime on the production floor, the logistics planner at headquarters needs to know about it immediately so adjustments and re-routes can be made on the go while also notifying the buyer of a possible delay in delivery.

Flexibility

Flexible logistics means being able to pivot and adapt to the ever-changing reality of a global supply chain. When it comes to IT’s ability to accommodate logistics, flexibility is all about the ability to access data and make decisions based on dynamic criteria, changing parameters on the fly and seeing the results in real-time. Again, this helps to enable maximum flexibility for the logistics team in handling whatever disruptions pop up in order to maintain satisfied customers and a happy workforce.

Responsiveness

IT outages happen—this is a reality of doing business in today’s digitized world. What differentiates one IT department from another is how the team responds to these outages. Logistics decisions are often made in real-time, with data coming in, decisions being made, and action being taken all within a matter of minutes. When there’s an interruption in any step of that process, shipments can end up delayed, inventory can be damaged or lost, and in a worst-case scenario, people can be hurt (as in a natural disaster, for example). Responsiveness also refers to the speed with which IT can deploy new solutions. If a logistics planner requests a system upgrade to be on par with the production team, your ability to get the ball rolling, get the paperwork in front of the right people, and get the upgrade in place is critical to logistics continuing to function as part of a cohesive supply chain.

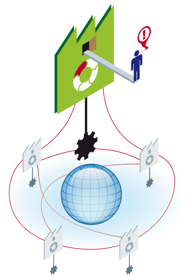

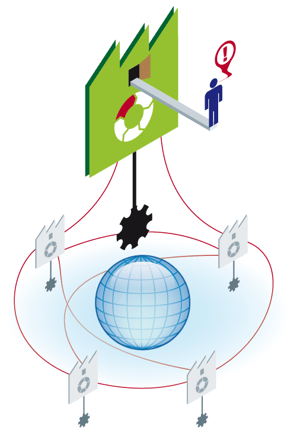

Cutting-edge technology

For a supply chain, not to mention a logistics network, to function in today’s agile reality, it needs to be on the cutting edge of industrial technology. The Internet of Things (IoT), Industry 4.0, Logistics 4.0, and mobile tech are all essential to today’s supply chain management and logistics success. Combined with the robust infrastructure discussed above and a modern SCMS solution running advanced analytics, your logistics arm will be at the forefront of maintaining smooth operations and a dedicated customer base.

Mobile access

Workers in today’s world thrive on instant access to data. Be it reading Facebook updates on a lunch break, or retrieving instant updates on the state of your trucking fleet, having access from a mobile device is key. In order for logistics managers to receive updates and send notifications from wherever they find themselves, they need systems that can connect to mobile-friendly interfaces or stand-alone apps. From the loading docks, while stuck on a plane, or while otherwise off-site your logistics manager will have access to the latest in real-time data with which to move forward and make those split-second decisions that keep shipments going out on time.

If you can ensure that your SCMS, ERP, and customer service solutions all meet this standard, your entire supply chain will hum along smoothly and your customers will stay happy. IT relies on the supply chain to receive hardware shipments, and on logistics to be sure the hardware they ship to remote sites gets there on-time and in one piece. Simultaneously, logistics rely on IT to provide the cutting-edge technology and high-speed infrastructure needed to integrate systems and speed data into analytics engines, all in the interest of keeping shipments moving on time. So what does an IT manager need to know about supply chain logistics? That as long as they can provide visibility and real-time dataflows, everyone from the CEO to your newest customer will remain happy and the chain will keep moving smoothly.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach