New ECG Guide to Finished Vehicle Logistics Forecasting Match the flexis S&OP Solution

Jessie MacAlpine - July 27, 2023

The ongoing uncertainty in global supply chains is impacting every level of manufacturing in the automotive industry, from sourcing parts to shipping finished vehicles. Even with a robust S&OP plan, companies can quickly be overrun by the ever-changing logistics and transportation planning necessary for finished vehicles. In considering some of the largest global vehicle manufacturers, the sheer scale of production requires careful planning to optimize resource usage.

New ECG Guide to Finished Vehicle Logistics Forecasting

In 2015, the Association of European Vehicle Logistics (ECG) created the ECG Capacity Working Group to address ongoing issues with logistics forecasting. By 2017, the board was tasked with creating a toolbox of good practices for transportation planning. Recently, the ECG board created a new document that sets out guidelines for OEMs and Logistic Service Providers (LSPs) to establish a production cycle that supports accurate and reliable logistics forecasting.

ECG Identifies 4 Key Steps for Optimized Vehicle Logistics Planning

1. Initial Production Planning and Sales Review

First, companies should start with an assessment of their current sales and production forecasts and then confirm those predictions with the S&OP team for the short, medium and long-term planning horizons.

2. Build a Forecasting Plan

Next, companies should develop a logistics plan based on the forecasted sales, the production plans, the specific flow of the products and their required geographic distribution.

3. Approve the Forecasting Plan

Then, the S&OP team will take responsibility for the distribution plan. The final products will be issued to LSPs for approval, and they will take final responsibility for fulfilment of the logistic plans.

4. Continuous Optimization

Finally, as part of the standard planning process, the cycle should include a regular review of how well forecasts for production and logistics matched in reality.

Planning for the Circle of Production

Overall, the new guidelines outline the importance of creating a standardized process for the production cycle, including monthly forecasting, review, and logistics planning. Each production cycle should begin by assessing how well the previous period’s projections aligned with the final sales and order execution. Then, the next period’s logistics planning should begin, aligned with sales and production planning. Finally, sales, production, and logistics metrics should be collected for a new cycle of assessment. Importantly, projections should always be compared to a series of input data, including historical sales, wholesales, and a risk assessment for the current supply chain.

An example of a production cycle from the 2023 ECG Guide to Finished Vehicle Logistics Forecasting.

The flexis Solution Aligns with New ECG Guidelines

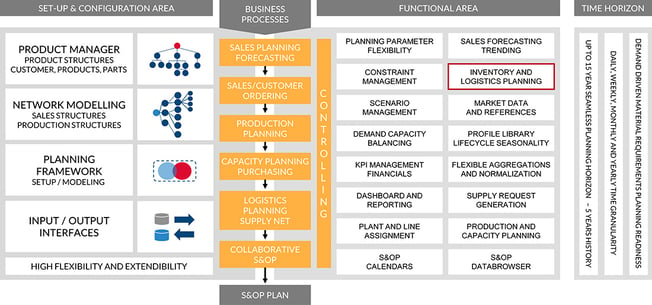

The flexis S&OP 4.0 solution offers integrated planning functions that align with all the guidelines outlined in the new ECG document for optimizing transportation planning.

“Our flexis S&OP solution exactly covers the process suggested by the ECG Guidelines. The software takes into account empirical values from historical sales figures, current sales figures and creates a sales plan for all levels of product and distribution hierarchies. On this basis, the system allows views on the production plan, capacity plan, purchasing plan and the necessary subsequent transportation plan. We call this a ‘collaborative S&OP,’” said Robin Hornung, Business Lead S&OP and Managing Director flexis Consult GmbH.

The flexis solution supports OEMs and manufacturers in precisely planning for customer demand and generating smart production plans for their complex and highly variant product structures and global markets. S&OP 4.0 ensures smooth and sustainable production logistics while eliminating supply chain risks through intelligent sales planning, production ordering and capacity management. With integrated AI capabilities and through constant balancing of demand and capacity, customers achieve up to a 15% increase in sales, up to a 20% reduction in distribution costs and up to a 20% increase in profitability. flexis has continuously demonstrated success with their solution suite, including saving time and costs for vehicle outbound planning for a major vehicle manufacturer.

The flexis solution supports end-to-end production planning and execution that aligns with the new ECG guidelines for Finished Vehicle logistics.

If you want to learn more get your Guide to S&OP. In this Guide you will learn:

-

Why an S&OP Business Process is so Important

-

Flexible and Quickly Implemented: S&OP from the Cloud

-

Central Tasks of the S&OP

-

Why an S&OP Is The Key to More Productivity

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach