How To Make Your Transportation Fleet More Sustainable

Keith LaBotz - February 23, 2023

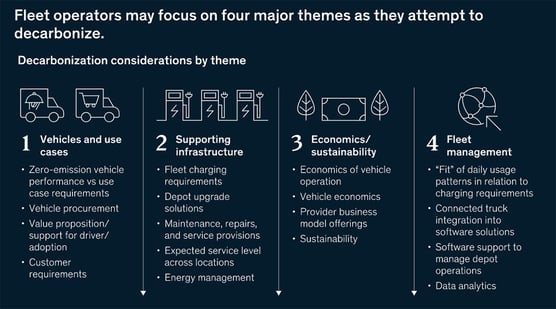

Fleet decarbonization can significantly improve supply chain sustainability, and it can also be risky and complicated. Most operators quickly discover greening a transportation fleet is more complex than replacing higher-emission vehicles with greener alternatives.

According to a recent McKinsey survey, fifty-three percent of fleet operators need more expertise to navigate the transition. That doesn’t mean the remaining 47% have a viable transition strategy.

Logistics constraints, costs, and dependencies exist for each vehicle, and changes cannot sacrifice competitiveness. Any change should increase operational agility by expanding risk mitigation options in light of uncertain energy policies and economics.

Source: McKinsey & Company

Meeting those objectives requires careful consideration of support infrastructure, fleet requirements, economics and sustainability, and vehicle characteristics. Analyzing pertinent costs, risks, and constraints is essential before initiating any changes to fleet equipment.

The Most Critical Step: Fleet TCO Analysis

Analyzing a fleet’s total cost of ownership (TCO) is the most critical step for ensuring a successful transition to a greener fleet. TCO calculates each vehicle's operating costs and carbon footprint in various roles and scenarios.

The best way to accomplish this is to use route planning software capable of performing “what-if” analysis for different combinations of vehicles and demand scenarios. The software must use a fleet’s unique requirements and actual demand data for accurate, realistic results.

Functionality Requirements for Fleet TCO Analysis

Practical TCO analysis requires software integrating vehicle routing and scheduling (VRS) algorithms with transportation planning. Integration with demand planning is even better; a good example is the flexis cloud solution, Transportation Planning and Scheduling.

Must-have functionality to look for includes:

-

Ingests raw order data from enterprise order management, WMS, fleet management, or SCM demand planning.

-

User-defined hypothetical fleets with customizable vehicle types, costs, constraints, and performance characteristics (see below for details).

-

Performs “what-if” scenario planning that generates executable delivery plans for a given set of orders using a variety of vehicle types.

-

Compares costs and carbon footprint of different vehicle types with current performance.

Vehicle characteristics and logistics requirements determine the results, so it’s essential software calculating TCO supports the most crucial variables:

-

Seasonal order volume, shipping requirements, and distribution locations.

-

Order product types, dimensions, and material handling requirements.

-

Vehicle type, charging and refueling times, and operating range.

-

Vehicle cost of acquisition, fuel consumption, and price, depreciation, wear, insurance.

-

Vehicle freight capacity and ability to transport certain products, load and unload times.

-

Route(s) driven, number of stops, and traffic patterns.

-

Dwell times at factories, customer docks, intermodal ramps, and ports.

-

Driver hours of duty restrictions.

What To Expect From Fleet TCO Analysis

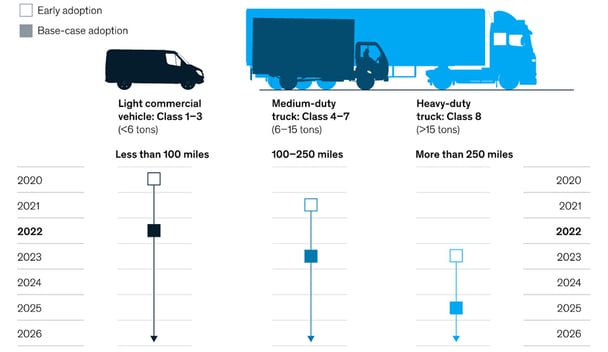

TCO analysis done right reveals the ideal ratio of vehicle types for a fleet and the expected reduction in carbon footprint. Given current vehicle and fuel prices:

-

Cost parity currently favors EVs in shorter-distance, lighter-duty vehicles in zones with a higher density of stops.

-

EVs for heavier, longer-range duty are projected to achieve TCO parity by 2030.

-

Natural gas-powered vehicles are viable in countries with stable, low-cost supplies.

-

Some fleets may find hydrogen fuel cell electric vehicles (FCEV) attractive for heavy-duty and long-haul trucking.

-

Intermodal or multimodal rail and inland waterways arrangements can be substituted for specific routes.

Source: McKinsey Center for Future Mobility

Solving the Dilemma of Fleet Decarbonization

A successful TCO analysis will reveal multiple options for a fleet, and that presents a dilemma when choosing lower-emission vehicle types:

-

Align all use cases under a common technology for simplicity or;

-

Leverage multiple technologies, increasing operational flexibility and complexity.

It’s like picking the winner from a pool of unknown contenders; no company has an advantage in predicting the future. The advantage lies in operational agility, avoiding choices that will box a fleet in when unexpected changes occur.

TCO Analysis Does Not Replace a Strategy

TCO analysis is a tool that reveals costs, emissions, and in some cases, a logistics execution plan. However, it does not provide a transition strategy for fleets - only your company can do that.

A dynamic strategy is best, remaining agile and open to unexpected changes in geopolitics, climate models, energy sources and policies, and technology. These have changed in the past and are likely to change again. If you doubt that, consider one of the big lessons from the past three years: expecting the unexpected leads to resilience.

Whatever strategy your company formulates, it must identify the technologies and applications that best serve its business model and objectives. When prioritizing use cases for TCO analysis, you may want to evaluate results from two perspectives:

-

Prioritizing use cases for the most profitable vehicle classes and routes with the best TCO results.

-

Prioritizing use cases that produce the most significant emission and cost reductions.

Conclusion

Fleet decarbonization requires careful analysis that leads to an agile strategy, and TCO analysis is a crucial first step. flexis solutions support analysis and help to identify the safe, profitable path to a greener fleet.

If you want to learn more get your Guide to Logistics 4.0

In this Guide you will learn:

-

Why a strategic process in transportation planning is a top priority for digitalization

-

What megatrends will increase supply chain volatility

-

How to manage it

Want to learn more about Multimodal Transportation?

Download our presentation and learn:

-

How can transports be planned quickly and yet flexible so that CO2 savings are verifiable?

-

How do you make optimal use of a multimodal transport network that maintains supply in both the short and long term?

-

How can you more easily realize a modal shift when disruptions occur? And how do you keep a grip on your CO2 emissions in doing so?

flexis and BigMile present a Use Case of a modal shift and show that network optimizations and sustainability often go hand in hand.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach