How Leveraging RFID Technology Enhances Supply Chain Visibility

Nick Ostdick - August 30, 2016

In a recent blog entry, we examined the technology trend known as the Internet of Things and how digital connectivity and optimization is rapidly making it easier for supply chain managers and planners to achieve end-to-end supply chain visibility and transparency. The IOT and other smart supply software solutions provide, among other functions, real-time reporting and data management of products, but what good are these capabilities without intelligent systems to track and manage the location and conditions of products?

In a recent blog entry, we examined the technology trend known as the Internet of Things and how digital connectivity and optimization is rapidly making it easier for supply chain managers and planners to achieve end-to-end supply chain visibility and transparency. The IOT and other smart supply software solutions provide, among other functions, real-time reporting and data management of products, but what good are these capabilities without intelligent systems to track and manage the location and conditions of products?

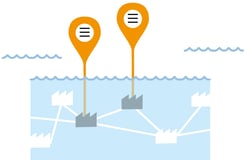

Enter Radio Frequency Identification (RFID), which is quickly becoming an important tool to leverage in achieving supply chain agility and transparency – especially as the supply pipeline continues to globalize and enter new and emerging markets. RFID technology utilizes tracking tags attached or embedded in objects to instantaneous identify the location and condition of these objects without the use of barcodes or scanners. These tags also contain and store information about the object – for example, a RFID tag on a head gasket may include such information as when the gasket was produced, where, when it was shipped to a warehouse, and more.

In terms of streamlining supply streams and creating the most cost-effective management solutions, it’s easy to see how RFID technology can enhance overall supply chain optimization and visibility. RFID provides supply managers and planners with precise product locating capabilities, reduces labor costs, and increases reporting and inventory accuracy by significantly decreasing the potential for costly errors via manual tracking and warehousing methods.

But where RFID technology really becomes a value-added proposition for efficient supply chain logistics is warehouse and transportation management. The ability to digitally track, record, review, and share important data and reporting about where a product is located, where it’s headed, and how it’s going to get there is vital to creating a cohesive supply strategy.

Warehouse Management

In today’s global supply chain environment, warehouse management doesn’t mean one hub or facility in a centralized location. Warehouse management is a much more complex and intricate set of tasks that spans multiple hubs in a variety of locations and markets with unique make-ups and challenges. As such, supply managers and planners need responsive, integrated systems that can provide real-time data and analysis to streamline supply processes and implement safety net strategies for potential breakdowns and bottlenecks. The days of manually scanning barcodes as products arrive and leave – and the manpower and resources associated with this mode of operation – are long gone for supply managers who want to engender best practices for sustainable growth and profitability.

Leveraging RFID technology to facilitate more efficient warehouse management practices can provide supply managers with:

- Real-time inventory levels to help increase supply chain visibility and agility.

- Improved management of cargo flow to create more efficient receiving and storing of products.

- Increase product location capability through the tracking and storage data for incoming and outgoing products

- Centralized access point for data and reporting that can then be shared with those across all points of the supply chain to foster coordination and collaboration of supply goals and objectives.

Transportation Management

If the warehousing of products in a growing, global supply landscape is a complicated process with various entry points and hurdles, then the transportation of products from a manufacturer on one side of the world to a distributor or supplier can be just as tricky. Whereas supply chain managers are primarily concerned with the product when it comes to warehouse managements, effective transportation management involves several other factors including fuel costs, route efficiency, equipment maintenance, and more. These concerns also require suppliers to think beyond the product on the shelf and account for elements often beyond their control, such as weather conditions, the geography of a region, and taxation and tariffs on the shipping and receiving of goods.

Leveraging RFID technology to facilitate more effective transportation management strategies can provide supply managers with:

- The ability to track shipping containers and fill-levels at each point in the shipping or freight process.

- Real-time freight yard and dock data and reporting to assess whether to leverage rail or chassis transportation and the costs associated with each mode.

- Fuel consumption and route efficiency data to make the most delivery-reliability decisions to maximize customer satisfaction and reduce freight costs.

- The capability to monitor wear and tear on equipment such as shipping containers, rail cars, trucks, and more to make informed, cost-effective maintenance and replacement decisions.

It’s impossible to manage and plan what you can’t actually see. Utilizing RFID technology as part of an integrated supply chain strategy allows planners and managers to more accurately see the supply landscape from a variety of different angles, implement supply stream solutions, and evaluate the results of these solutions to strive for end-to-end supply visibility and agility.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach