How End-to-end Visibility Can Impact Your S&OP

Jesse Kelber - January 14, 2020

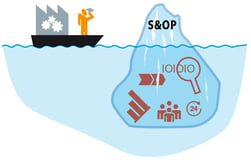

You’ve all heard the saying, “the left hand doesn’t know what the right hand is doing.” This encapsulates many organizations' approach to sales and operations planning, or S&OP. Too often, companies fail to include all the relevant stakeholders and departments in their S&OP process, leading to major sections of the supply chain being left out. For a process that impacts every aspect of a manufacturing concern, this seems not only short-sighted but also like a potentially catastrophic oversight. On the other hand (no pun intended), when a company’s S&OP process is run by an integrated team that includes representatives from the C-suite, sales & marketing, production, inventory, all the way to logistics—the outcomes can improve drastically.

You’ve all heard the saying, “the left hand doesn’t know what the right hand is doing.” This encapsulates many organizations' approach to sales and operations planning, or S&OP. Too often, companies fail to include all the relevant stakeholders and departments in their S&OP process, leading to major sections of the supply chain being left out. For a process that impacts every aspect of a manufacturing concern, this seems not only short-sighted but also like a potentially catastrophic oversight. On the other hand (no pun intended), when a company’s S&OP process is run by an integrated team that includes representatives from the C-suite, sales & marketing, production, inventory, all the way to logistics—the outcomes can improve drastically.

On a fundamental level, the sales and operations planning process is about managing supply and demand within your supply chain. The goal of any manufacturing supply chain is delivering finished goods, on time, to happy customers. As such, collaboration between the departments involved in overseeing each segment of that supply chain is critical. According to a study by APQC, nearly ⅓ of respondent companies don’t include purchasing and production, and ½ don’t even include logistics in their planning cycles. Without visibility into the entire, end-to-end supply chain, how can these companies hope to achieve a truly accurate S&OP roadmap? Arguably, they can’t—since it’s the data input from each and every segment that informs the analytics that make the plan possible. For each section of the chain that’s missing from that input dataflow, a piece of the output plan will be that much less accurate.

The question is, how do you make sure as few sections are missing as possible?

Visibility into Individual Supply Chain Segments Is a Good Start

Start with the foundational segments of your value chain: production, inventory, and logistics. Not only will this will give you a solid grounding and a flow of data to build on as you add segments, partners, and stakeholders, it will also set the stage for the optimal integration of each of the following segments:

Production

IoT sensors on your production equipment can feed data on production levels directly into your S&OP analytics interface for real-time analysis. The benefit to your S&OP is in ensuring the process is working with the most up-to-the-minute capacity numbers possible.

Inventory

RFID tags on inventory and tracking on pallets mean your real-time dataflow will include the locations of each order’s component parts as they’re shelved. This allows for orders to be grouped closer together for faster picking and packing and lowered holding costs. As for the S&OP process, this additional real-time data lets your planner make group orders and cut turn around times reliably, helping improve your on-time delivery KPIs.

Logistics

GPS tracking of your shipping fleet brings this segment into the dataflow. If you can get word of a potential disruption and re-route your trucks in real-time, your on-time delivery numbers will soar. And when the plan created by your S&OP includes relevant logistics information, it will better reflect this new real-time reality as well.

Next, Add Your Up- and Down-Stream Partners

Once you have visibility into your core supply chain stages, it’s time to integrate this data with your up and downstream partners’ ecosystems. This will round out the end-to-end visibility your S&OP process needs for optimal accuracy and effectiveness. Sales and operations planning best practices include having all available data flowing into the analysis stage. The AI-powered realities of today’s advanced analytics engines means the quality of the plan generated will match the quality of the data being input. High quality data yields high quality analytics. The reverse is also true: the output from poor data will necessarily be poor. So it’s crucial to have high-quality data from each stage in order to see these efficiency gains.

End-To-End Supply Chain Visibility Leads to Amazing Insights

Two key components of a solid S&OP process are predictive analytics and probabilistic modeling. Each of these is powerful in its own right, but the truly astounding impact they can have when combined is why we’re aiming for end-to-end visibility. Advanced analytics like predictive algorithms mine the data being generated by your supply chain technology and use it to predict future patterns and events—all in real-time. This goes far beyond standard demand forecasting (though these tools can make those forecasts far more accurate), incorporating data from consumer buying trends to weather patterns to predict the impact on your bottom line. Probabilistic modeling does something similar, only with historical data. By taking into account previous demand spikes, shipping disruptions, and more, these models can accurately determine the likelihood of similar events occurring in the future.

For these technologies to be as effective as possible, they require data from the entire supply chain. Any Industry 4.0 tools you’ve deployed, along with those of your partners, will provide the needed visibility to generate that data. The feed from your upstream suppliers, the sensors on your production line, the tags in your warehouse, and the trackers throughout your logistics are the key sources. The data provided by these technologies feed the algorithms and analytics engines that will give your S&OP the boost it needs to start producing the most accurate and efficient plans possible.

Given the increasing complexity of today’s digital supply chain, it’s imperative that companies who want to stay competitive put in place the systems that will give them end-to-end visibility into their own value chains. It’s this visibility that provides the foundation for the powerful analytics necessary to generate the most accurate sales and operations planning process ever possible. If your S&OP process doesn’t include stakeholders from each of the stages of your supply chain, or if there are data silos located with one individual or team, steps need to be taken to break down those silos and incorporate each of those stakeholders. It’s only then that you’ll be able to integrate the dataflows from up and down the chain into one coherent set of data for your analytics to work with. And it’s that data set, only attainable with complete supply chain transparency, that will power optimal S&OP workflows.

LATEST POSTS

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers

- Optimizing Human Resource Scheduling in Manufacturing: A Technological Approach