3 Systemic Supply Chain Risks You Need To Tame

Keith LaBotz - March 23, 2023

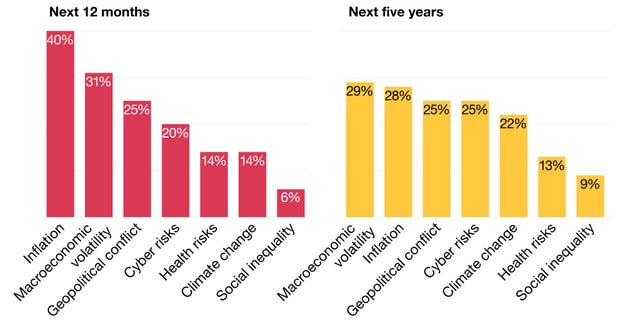

PricewaterhouseCooper’s (PWC) 26th annual "Global CEO Survey" polled 4,410 CEOs in 105 countries to get their take on business risks. If you want the zeitgeist on supply chain risk, this summary of executive outlooks is interesting, but the most valuable information may be PWC’s conclusion that the risks are interconnected.

Source: PwC’s 26th Annual Global CEO Survey

That’s hardly a novel idea, but what is new is that the connection between supply chain, government, and financial systems is stronger than ever before. The global supply chain is a network of networks, and the network itself is changing the nature of supply chain risk, exposing companies to systemic risks. Understanding this risk will enable your company to mitigate it effectively.

Why is that important for your company? A McKinsey study reports that most organizations cannot measure and monitor vulnerabilities. Only 2 percent of senior supply chain executives understand risks beyond 2nd tier suppliers. That’s a serious problem because most disruptions originate in deeper supply chain tiers; risk mitigation efforts need to target the right places.

Knowing where to concentrate mitigation efforts is challenging, and systemic risk is difficult to see - it’s an inherent quality. You may be looking in the right place, but it remains invisible until you change perspective, raising a more interesting paradox.

Systemic supply chain risks are inherent in the most powerful features of the network that companies need to increase profits, sustainability, and risk mitigation. Who would suspect that these features are also the most destructive? Things are not always what they appear, especially when assessing risks.

Another challenge is that supply chains are growing more complex, changing how risks propagate. But risk mitigation has stayed the same for many organizations, and it's often approached as it was thirty years ago, concentrating on first-tier suppliers and vendors. Risk strategy must evolve with the network, and addressing growing systemic risk is part of this change.

The primary goal of any risk strategy is to prevent disruptions where possible and respond optimally. An effective response considers the impact on a supply chain and adjusts planning and execution to achieve optimal outcomes. Understanding systemic risk can help your company formulate a more effective strategy, and this article suggests a solution to make that easier.

Supply Chain Risks Are Interdependent

The most significant point in the PWC survey for supply chains is that risks are reinforcing and compounding one another. PWC cites the conflict in Ukraine as an example, noting increasing prices encourage central bank intervention with growth-dampening interest rate hikes. Economies and supply chains are affected as a result.

That is an example of systemic risk; previous posts refer to it as a supply chain wildfire. Let’s look at three features of supply chain systems that have the most power to increase and decrease risks, not just for supply chains but in every aspect of modern life.

Supply Chain Systemic Risk #1: Digitalization

Digitalization enables supply chain integration and increases volatility.

Integration of supply chain processes enables efficiency and optimization; it eliminates waste, erases operational silos, and increases the speed of execution. Boundaries blur, allowing interoperability and sharing of information across networks. These qualities are essential for effective risk management in a supply chain. For example, real-time visibility, flexis multi-dimensional monitoring, and transportation optimization depend on systems integration.

Now for the dark side of digitalization. As supply chain velocity increases with integration, so does volatility. Integration multiplies the number of systems interfaces, increasing the potential sources and targets of disruptions in a process.

Conclusion: The potential increases for more disruptions that arrive faster. Does that sound like volatility? You know the answer if it walks and quacks like a duck.

Supply Chain Systemic Risk #2: Networking

Networking enables widespread collaboration that amplifies positive and negative interactions between the parties.

The global supply chain is a network of networks, a digital metasystem of financial, political, and supply chain systems. Disturbances ripple through the network, and some cause instant volatility, while others compound over time as they reverberate through the supply chain, triggering subsequent waves of disruptions.

- The financial, political, and supply chain facets pass disruptions back and forth - nothing happens to one without affecting the others.

- Contagion risk increases with network size, transferring costs further and faster.

- Network effects strengthen with network size, amplifying the magnitude and frequency of disruptions.

- A global supply chain connects with financial and political powers around the globe, making the network directly vulnerable to geopolitical turmoil.

Conclusion: Everyone wins and loses together in a network. Political and financial mishaps incite supply chain volatility and vice-versa, and it gets more complicated when there is a conflict in the network.

Supply Chain Systemic Risk #3: Globalization

Globalization increases economic benefits globally and vulnerability to geopolitical disturbances.

The past thirty years were relatively peaceful, coinciding with explosive growth in digital technologies, and these conditions allowed globalization to flourish. The global supply chain was built around these assumptions with only one gear: forward.

Conclusion: Without being able to back out and do business in an alternative supply chain network, companies can expect volatility as long as there is a geopolitical conflict or a new network forms.

The Solution to Systemic Supply Chain Risks

Expanded digitalization, networking, and globalization are essential for advancing supply chain goals, and they increase systemic risk. The push to promote these three features will likely stay strong, resulting in more supply chain volatility.

Because systemic risks cannot be prevented, the most effective mitigation strategy is for supply chains to respond optimally to disruptions. That requires supply chain optimization software to adjust planning and scheduling across all supply chain functions. The software must determine the most effective utilization of resources among partners to keep plans on track.

For example, the flexis suite of apps integrates transportation, S&OP, APS, and SCM (logistics) planning and execution. This cloud-based solution continuously responds to disruptions by adjusting planning and execution across supply chain processes from sourcing thru production and final distribution.

Short-term and long-range planning evaluates potential risks, reducing exposure to potential volatility. Some of the capabilities the flexis suite employs to mitigate risks include the following:

- Global visibility and monitoring of orders and shipments in the supply chain.

- Iterative optimization between production, fulfillment, and transportation capacity.

- Detection of disruptions like changes in demand, productivity, resources, port bottlenecks, and transportation capacity.

- Continuous optimization of long-range forecasting (6 + months), mid-range tactical planning (3-6 months), and daily operational plans (from minutes in advance out to 12 weeks of execution).

Conclusion

Systemic risk will likely increase as digitalization expands in supply chain, government, and financial networks. The most effective mitigation strategy is assuming greater volatility will result and optimizing supply chain planning and execution in response to disruptions. flexis AG provides the software and services that enable companies to implement this approach.

If you want to learn more get your Supply Chain Manager's Guide to AI

In this Guide you will learn:

-

Why AI will define the future of the Global Supply Chain

-

Applications of AI for Manufacturers

-

Keys to successful AI integration with S&OP

LATEST POSTS

- Understand Why Production Planning Needs Specialized Solutions

- Understand Circular Economy in The Manufacturing Industry

- How Can Industry 4.0 IT Integration Be Achieved Smoothly?

- The Significance of Order Sequencing in Discrete Manufacturing

- How to improve your Supply Chain Management: The Power of Control Towers